I've heard a lot the last couple of weeks regarding our top balance/bottom balance situation. Most of the online forum engineers did NOT skip a beat. They went off of current shunt balancers pretty much cold turkey, but immediately lunged to monitoring individual cell voltages for a "low voltage limit" as the holy grail of the NEW BMSpeak. It was awe inspiring to watch. The entire conversion from shunt balance to LV cell limits took what looked like 8 minutes. Several new forum topics were started on the new design and ONE guy is already taking orders for his NEW design. I had a bit of a private e-mail conversation with him to avoid embarrassing him and it became immediately clear he had no clue how a charger worked to charge a battery.

So today, after a weeks work on this opus, I've posted a 102 minute epic adventure on the website at http://evtv.me on how to charge a LiFePo4 battery, and what a constant current/constant voltage charge curve is. If you already know, FEEL FREE TO SKIP THIS ONE. It was boring even for me.

But what is lost in all this is the question I keep asking them, and they seem TOTALLY UNFAZED by it. You are monitoring for WHAT and you will do WHAT with the information if you find it?

The problem of course is that voltage is a function of current based on the internal resistance of the cell. And that internal resistance varies both ACROSS the entire discharge curve, and by temperature. So whatever voltage you set, will cause a different result at a dramatically different temperature. So design and test in December will not have the same results in June. And the REAL problem is the voltage at all. It sags at the beginning of the curve, but it sags MUCH more at the end of it. And at some discharge currents can drop to very low values with NOTHING wrong with the cell, in fact everything very very RIGHT with the cell, since it can deliver that kind of current.

So if I WANTED to set an alarm, and could magically do it at NO effort or expense, such that if ANY cell fell below some voltage, and simply set off an alarm, I would have NO idea what to set it at anyway. Or what to do with the information if it went off.

But I have gotten some new equipment and can do some pretty good current rates out of single cells. I did some discharging of a Thundersky 160 Ah at 300 amps with a duty cycle of 20 seconds at 300 amps discharge, followed by 20 seconds rest and repeated until full discharge. It appears this CAN cause a modest Peukert effect.

Today, I had a bit more productive fun with a THundersky 90Ah and a Sky Energy 100 Ah cell. Topped them both off quite nicely, and then did a discharge curve in an odd combination with the West Mountain automated load and writing down the values. I set it to discharge for 180 seconds and rest for 60. For both cells, that worked out to about 5% increments of total capacity for each 180 second pulse - 4.5AH for the Thundersky and 5.0 AH for the Sky Energy.

What I found was encouraging and discouraging. First, these little batteries are REMARKABLE devices in how much power and current they can spew for hours on end. Discouraging? Well, I had been working on a little Arduino board to drive the ancient fuel gage in the Speedster's original combi gage. Had it working pretty good and just assumed that the voltage decline, while very slight, would be very linear and at least detectable. Wrong.

I've been spending way too much time on the ugly end of the discharge curve. Up at the GOOD end where all of you all want to be, the voltage differences are very small. Several people have told me you cannot monitor pack state of charge by voltage. I pretty much blew them off. The voltage changes with discharge, I've got meters. I can measure it.

Well, I STAND CORRECTED. They were precisely correct. UP in the good part of the curve, there is so negligible a change in voltage that it is just not really very useful. I will have to do AH counting with the Arduino instead of simple voltage measurements. No fuel gage based on voltage will work.

Why did I think it would? Well down on the ugly end, if you can get unloaded for a minute and check your pack voltage, that's a pretty GOOD indicator down there. When it goes below 3.00 v static, you are pretty much done. And I've always said that there wasn't much left after that.

Well how TRUE TRUE TRUE. And with good reason. Your static voltage will dip below 3.00 v at about the 95% discharge level. And there really ISN'T any left. But recall that we get 2000 cycles at 80% DOD and 3000 cycles at 70% DOD. Up on THAT part of the curve, voltage is essentially useless.

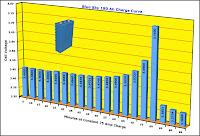

See the graphs below. They tell the story.

I guess the only other interesting thing is that the Sky Energy cells, which I had said seemed to have a flatter discharge curve, seemed that way because they have a flatter discharge curve. Actually quite a bit flatter.

So a couple of things to learn from this. 1. Current load causes dramatic changes in voltage, but they are almost impossible to relate to useful information. They are just going to sag under heavy currents. These graphs are at 1C. It is much worse at 3C or 4C.

2. A fuel gage for an electric car using LiFePo4 cells, that is useful in the upper range of the battery and useful for detecting either 70% discharge or 80% depth of discharge, can NOT use voltage as a metric. It MUST count actual Ampere Hour usage. I know of no other way.

Enjoy.

Jack Rickard

Tuesday, December 22, 2009

Wednesday, November 25, 2009

GET RID OF THOSE SHUNT BALANCING CIRCUITS

As you may know, I've been a bit at odds with the cognescetti of the EV community on the topic of Battery Managements Systems, and particularly of the form of shunt balancing circuits. They're pretty much unified in the position that you have to have them or you will kill your expensive LiFePo4 batteries.

My position is that they are dangerous, a fire hazard at most and an annoyance at least.

One of the problems I have in life is that I'm often surrounded by people that are extremely sure of themselves and their positions. I'm never quite sure. Almost everything COULD be a couple of different ways, and most probably is, and I've probably got at least part of it wrong.

The oddity is that the ones most certain, are the those most certain to be in error. And if I run into a man with a theory, who isn't quite sure, I can often find valuable, and sometimes extremely valuable information there.

Those who most loudly voice their absolute certainty, almost inevitably lead me into something totally erroneous, and they then bleat piteously about "unintended consequences" and the simple unavailability of such information back when they were so sure.

Last week we aired a kind of a tutorial on using the Manzanita Micro PFC-75 charger. Despite some kind of bizarre design choices, I like this device and it is undoubtedly the most powerful single phase charger on the planet at this point. Along the way, I had a conversation with Rich Rudman, about the device of course.

But we also discussed his "Rudman Regulator" and the new MkIII device he's working on for LiFePo4 cells. Mr. Rudman was EXTREMELY emphatic that without some form of battery management system, I would kill numerous cells. His solution would have been $7000 for the Mini Cooper. He told me that they had spent THOUSANDS OF HOURS testing these cells and that balancing was imperative.

This made me feel quite badly. In truth I have NOT spent THOUSANDS of hours testing batteries. I've spent a lot of time, but it is not very rewarding work. It takes HOURS to charge a cell. You have to pretty much observe it closely the entire time to log any meaningful data. It then takes HOURS to discharge it, and again, you can't even really turn away from it. So it's long, boring, and tedious.

Some of it IS fascinating. Mostly once you've collected all this and are going over it. But the actual testing is pretty gruesome.

There are 2040 work hours in a year at 40 hours per week. I may have HUNDREDS of hours testing batteries, but certainly not THOUSANDS. And he was so certain of his results, it rather sent me back to the lab.

The "lab" isn't precisely so. I can test single cells on the back workbench where I have a lot of test equipment. And I often test 4 cell or 8 cell banks. But a string of series cells to be tested poses some problems in dumping that much power during discharge. So we use GEM's and in fact have from the beginning.

GEM's are Global Electric Motorcars. I had three of them, now down to two. Ours are like little pickup trucks. They require no licensing. They are Neighborhood Electric Vehicles, typically limited to 25 mph. They have a small 7.5 HP motor and a simple GE controller.

So this week, I took some time, and brought my really pretty nice Agilent 5 1/2 digit multimeter from the back bench, along with the test device I built for the Mini.

It took 2 full days, but I very precisely hand balanced all 24 cells to precisely 4.000 volts.

The tester lets me add 3 amps of charge to a cell. And it also lets me bleed 3 or 5 amps from a cell through some 50 watt resistors. Although it has a built in voltmeter, I used the Agilent for precision.

Of course the problem is that if you add a bit of energy to a cell, or for that matter delete a little energy from a cell, it kind of "bounces". The voltage indication will change, for example going higher when charging. But when you quit, it will sag back down a little bit to it's stable level. Similarly when discharging, it will decrease the voltage alright, but when you remove the load, it bounces back up a bit. So this "manual" balancing is a bit tedious. But I can make sure this way that they ARE in fact balanced.

This is normally the function of these shunt regulator active cell balancing devices. This is typically a small circuit with a voltage regulator chip controlling a larger MOSFET or transistor that "shunts" current across the cell terminal when the cell reaches a set maximum voltage. This usually uses a current limiting resistor which dissipates some of the heat.

The theory is that you hook up your serial string of cells to a charger. When one cell gets to the voltage set point, 3.8 vdc or 4.0 vdc, or whatever, the shunt goes into conduction. The rest of the cells continue to charge, but the cell in conduction is held at this maximum voltage.

Once ALL the shunts are in conduction, the cells are thought to be "balanced" in that they are all held at the same maximum voltage.

I've examined the cases of several fires wherein electric cars burned to the ground. Two culprits emerge as likely causes. Battery modules made of large numbers of small cells, and shunt balancing circuits.

So I've avoided them.

But after my discussion with Mr. Rudman, who has been doing electric cars for many years, has one of the most respected charger products in the community, and who personally assured me that after THOUSANDS of hours of testing, he's utterly convinced you MUST have a battery management system, I simulated it in this fashion.

Then I went and drove the car. Actually I went through this process THREE times this week. And with the same result all three times - a totally destroyed battery cell. Irrecoverably discharged to 0.0000 vdc.

So I AM in fact destroying cells. And if I'm destroying them on this little 72 vdc 24 cell GEM system, IMAGINE how much difficulty I was going to have with 112 cells in the Mini and 72 cells in the Beck Speedster.

I was pretty depressed about it. Not only was I murdering cells in groups, but I was apparently pathologically unable to balance them sufficiently well to prevent it. And in fact the more precisely I balanced them, the worse the carnage became....

Uh..oh. Is this the sound of a clue?

Finally Friday morning it all came together. It is so obvious I'm embarassed by my own intellectual limitations and overall backwardness. But worse, I have to go public with it because there are a LOT of people spending a LOT of money on these shunt chargers to do precisely the same thing.

The problem is, the batteries vary in capacity. While capacity diminishes very gradually with time, there's really nothing you can do to change the capacity. It is what it is and it is that for each cell.

By very carefully charging each cell to precisely the same 4.000 level, I did indeed "balance" the cells - at least at the top of the charge.

But as I discharged the cells, they reached any arbitrary point on their discharge curve at DIFFERENT times. So at the end of the charge, where the knee of the discharge curve turns sharply down, they became more UNBALANCED at the bottom.

The graph below shows the number of seconds a cell has at a 100 amp discharge rate to 3.00 vdc from a full charge with all of the cells balanced at the top of charge.

The problem here of course is that some cells go over the knee first and start down the steep discharge wall at the end before the others. This has a very bad result. The cells still up on the plateau, making current, drive current through this smaller capacity cell and drive it down to zero volts and ultimately to destruction..

So I was repeatedly destroying cells by carefully top balancing the cells, precisely as a current shunt balancing circuit would, and then discharging past the knee of the discharge curve. The other cells turn on the weaker one and eat it like a pack of wolves.

Worse, your overall pack voltage masks all this - remaining up in the supposedly safe area.

The solution appears to be BOTTOM balancing. With all the cells discharged, I replaced the dead one, and balanced all the cells at 2.90 vdc. Then recharged the pack to 87 vdc (3.625 vdc per cell).

Now the cells are very unbalanced at the top - some slightly over 4 volts and some quite under the 3.625 average.

But I don't care about the top. I don't lose cells at the top, and we're charging at 20 amps. During discharge, even the GEM can go over 200 amps of current. That is a 10x more violent event in the life of a battery. And a weak cell can drop from 2.8 to 2.0 to 1.0 to 0.0 in a matter of a dozen seconds or so at 200 amps.

This pretty much explains why I was able to lose cells on the GEM while balancing to the nth degree, but the Speedster, whose cells have never been balanced at all, wheels merrily along without problems.

In fact, we recently completed a 107 mile test drive with the new tires and really did push the little car to the limit. At the end, all of the cells measured between 2.8 and 2.9vdc in quite balanced fashion - at the BOTTOM of the discharge curve. Things were good BECAUSE we had never top balanced.

What I conclude from this is that these simple current shunt balance circuits are not only a needless expense and a fire hazard, they are doing exactly the opposite of what they purport to do. They are UNbalancing the pack at the bottom where it matters, and potentially leading to the untimely death of cells.

So we're still in search of the perfect Battery Management/Monitoring system. But the current shunt balancers are certainly not it. Save your money, and your batteries.

Jack Rickard

My position is that they are dangerous, a fire hazard at most and an annoyance at least.

One of the problems I have in life is that I'm often surrounded by people that are extremely sure of themselves and their positions. I'm never quite sure. Almost everything COULD be a couple of different ways, and most probably is, and I've probably got at least part of it wrong.

The oddity is that the ones most certain, are the those most certain to be in error. And if I run into a man with a theory, who isn't quite sure, I can often find valuable, and sometimes extremely valuable information there.

Those who most loudly voice their absolute certainty, almost inevitably lead me into something totally erroneous, and they then bleat piteously about "unintended consequences" and the simple unavailability of such information back when they were so sure.

Last week we aired a kind of a tutorial on using the Manzanita Micro PFC-75 charger. Despite some kind of bizarre design choices, I like this device and it is undoubtedly the most powerful single phase charger on the planet at this point. Along the way, I had a conversation with Rich Rudman, about the device of course.

But we also discussed his "Rudman Regulator" and the new MkIII device he's working on for LiFePo4 cells. Mr. Rudman was EXTREMELY emphatic that without some form of battery management system, I would kill numerous cells. His solution would have been $7000 for the Mini Cooper. He told me that they had spent THOUSANDS OF HOURS testing these cells and that balancing was imperative.

This made me feel quite badly. In truth I have NOT spent THOUSANDS of hours testing batteries. I've spent a lot of time, but it is not very rewarding work. It takes HOURS to charge a cell. You have to pretty much observe it closely the entire time to log any meaningful data. It then takes HOURS to discharge it, and again, you can't even really turn away from it. So it's long, boring, and tedious.

Some of it IS fascinating. Mostly once you've collected all this and are going over it. But the actual testing is pretty gruesome.

There are 2040 work hours in a year at 40 hours per week. I may have HUNDREDS of hours testing batteries, but certainly not THOUSANDS. And he was so certain of his results, it rather sent me back to the lab.

The "lab" isn't precisely so. I can test single cells on the back workbench where I have a lot of test equipment. And I often test 4 cell or 8 cell banks. But a string of series cells to be tested poses some problems in dumping that much power during discharge. So we use GEM's and in fact have from the beginning.

GEM's are Global Electric Motorcars. I had three of them, now down to two. Ours are like little pickup trucks. They require no licensing. They are Neighborhood Electric Vehicles, typically limited to 25 mph. They have a small 7.5 HP motor and a simple GE controller.

So this week, I took some time, and brought my really pretty nice Agilent 5 1/2 digit multimeter from the back bench, along with the test device I built for the Mini.

It took 2 full days, but I very precisely hand balanced all 24 cells to precisely 4.000 volts.

The tester lets me add 3 amps of charge to a cell. And it also lets me bleed 3 or 5 amps from a cell through some 50 watt resistors. Although it has a built in voltmeter, I used the Agilent for precision.

Of course the problem is that if you add a bit of energy to a cell, or for that matter delete a little energy from a cell, it kind of "bounces". The voltage indication will change, for example going higher when charging. But when you quit, it will sag back down a little bit to it's stable level. Similarly when discharging, it will decrease the voltage alright, but when you remove the load, it bounces back up a bit. So this "manual" balancing is a bit tedious. But I can make sure this way that they ARE in fact balanced.

This is normally the function of these shunt regulator active cell balancing devices. This is typically a small circuit with a voltage regulator chip controlling a larger MOSFET or transistor that "shunts" current across the cell terminal when the cell reaches a set maximum voltage. This usually uses a current limiting resistor which dissipates some of the heat.

The theory is that you hook up your serial string of cells to a charger. When one cell gets to the voltage set point, 3.8 vdc or 4.0 vdc, or whatever, the shunt goes into conduction. The rest of the cells continue to charge, but the cell in conduction is held at this maximum voltage.

Once ALL the shunts are in conduction, the cells are thought to be "balanced" in that they are all held at the same maximum voltage.

I've examined the cases of several fires wherein electric cars burned to the ground. Two culprits emerge as likely causes. Battery modules made of large numbers of small cells, and shunt balancing circuits.

So I've avoided them.

But after my discussion with Mr. Rudman, who has been doing electric cars for many years, has one of the most respected charger products in the community, and who personally assured me that after THOUSANDS of hours of testing, he's utterly convinced you MUST have a battery management system, I simulated it in this fashion.

Then I went and drove the car. Actually I went through this process THREE times this week. And with the same result all three times - a totally destroyed battery cell. Irrecoverably discharged to 0.0000 vdc.

So I AM in fact destroying cells. And if I'm destroying them on this little 72 vdc 24 cell GEM system, IMAGINE how much difficulty I was going to have with 112 cells in the Mini and 72 cells in the Beck Speedster.

I was pretty depressed about it. Not only was I murdering cells in groups, but I was apparently pathologically unable to balance them sufficiently well to prevent it. And in fact the more precisely I balanced them, the worse the carnage became....

Uh..oh. Is this the sound of a clue?

Finally Friday morning it all came together. It is so obvious I'm embarassed by my own intellectual limitations and overall backwardness. But worse, I have to go public with it because there are a LOT of people spending a LOT of money on these shunt chargers to do precisely the same thing.

The problem is, the batteries vary in capacity. While capacity diminishes very gradually with time, there's really nothing you can do to change the capacity. It is what it is and it is that for each cell.

By very carefully charging each cell to precisely the same 4.000 level, I did indeed "balance" the cells - at least at the top of the charge.

But as I discharged the cells, they reached any arbitrary point on their discharge curve at DIFFERENT times. So at the end of the charge, where the knee of the discharge curve turns sharply down, they became more UNBALANCED at the bottom.

The graph below shows the number of seconds a cell has at a 100 amp discharge rate to 3.00 vdc from a full charge with all of the cells balanced at the top of charge.

The problem here of course is that some cells go over the knee first and start down the steep discharge wall at the end before the others. This has a very bad result. The cells still up on the plateau, making current, drive current through this smaller capacity cell and drive it down to zero volts and ultimately to destruction..

So I was repeatedly destroying cells by carefully top balancing the cells, precisely as a current shunt balancing circuit would, and then discharging past the knee of the discharge curve. The other cells turn on the weaker one and eat it like a pack of wolves.

Worse, your overall pack voltage masks all this - remaining up in the supposedly safe area.

The solution appears to be BOTTOM balancing. With all the cells discharged, I replaced the dead one, and balanced all the cells at 2.90 vdc. Then recharged the pack to 87 vdc (3.625 vdc per cell).

Now the cells are very unbalanced at the top - some slightly over 4 volts and some quite under the 3.625 average.

But I don't care about the top. I don't lose cells at the top, and we're charging at 20 amps. During discharge, even the GEM can go over 200 amps of current. That is a 10x more violent event in the life of a battery. And a weak cell can drop from 2.8 to 2.0 to 1.0 to 0.0 in a matter of a dozen seconds or so at 200 amps.

This pretty much explains why I was able to lose cells on the GEM while balancing to the nth degree, but the Speedster, whose cells have never been balanced at all, wheels merrily along without problems.

In fact, we recently completed a 107 mile test drive with the new tires and really did push the little car to the limit. At the end, all of the cells measured between 2.8 and 2.9vdc in quite balanced fashion - at the BOTTOM of the discharge curve. Things were good BECAUSE we had never top balanced.

What I conclude from this is that these simple current shunt balance circuits are not only a needless expense and a fire hazard, they are doing exactly the opposite of what they purport to do. They are UNbalancing the pack at the bottom where it matters, and potentially leading to the untimely death of cells.

So we're still in search of the perfect Battery Management/Monitoring system. But the current shunt balancers are certainly not it. Save your money, and your batteries.

Jack Rickard

Saturday, October 31, 2009

This Week on the Mini Cooper

The concept of a weekly show requires us to actually do some work each week. We had a very good week this past, the last week in October. It rained every day, so no goofing around in the electric Speedster.

We had done a video on the EVision installation. What we didn't show was all the wires we got in wrong. We spent a day troubleshooting this and finally got everything hooked up correctly. The display mounted in the air vent is absolutely gorgeous, and now gives me a way to monitor energy into and out of the pack.

This week's show is largely about DC-DC converters. Our pack voltage is nominally 375 volts. We charge to 392, but as soon as you remove the charger, it settles to about 375. The Mini Cooper is an absolutely AMAZING device. Normally, automotive manufactures add "features" that they can upsell to customers at additional cost. The BMW Mini Cooper is quite different. It has DOZENS of "hidden" features you will never know are there.

For example, the engine control unit, termed a DME in BMW parlance, has a power management system. A fuseblock just off the battery terminal allows it to monitor battery voltage, battery CURRENT and battery temperature. There are several levels of ON in this car. There is unswitched power to run the courtesy lights, remote control radio, power windows, doorlocks, etc. Then if you put the remote in it's little dock, the CAS computer starts waking things up. The system has a body K CAN bus, a power train PT CAN bus, a MORE bus for the radios, etc. And it brings up power in different "levels" or "terminals".

If the engine is running, and the battery starts to provide a lot of 12 vdc power, the DME can actually note this, and will very subtly increase engine RPM to increase alternator output.

This is just one example. The heated seats are another. They contain temperature monitors and when you turn on the heated seats, they don't just switch 12 vdc to some heaters. They monitor the switch at three levels, and the temperature monitor, and power the resistive heating elements with separate pulse width modulators.

This theme is repeated throughout the car. There are dozens of hidden items. The air conditioning and heating has temperature sensors at two points in the car, a SOLAR sensor to detect sunlight gain, temp sensors on the heat exchanger and air conditioning evaporator, etc. etc. etc. How much heat or air conditioning is not exactly a function of hi/med/lo on this car. It has a separate computer just to calculate how much hot/cold/fresh air to mix. VERY advanced. And hard for us country bumpkins to deal with in a way. But WHAT A CAR.

In any event, in this weeks show we look at some options for replacing the battery and alternator for this car with a pair of DC to DC converters. We talk about the Brusa model 412. This monster puts out 1725 watts of power (125 amps at 13.8 vdc from 375 vdc input). Very capable. But the falling dollar has likely put it out of reach of most at $3200.

We do describe how to combine three Kelly 125 vdc DC-DC converters to put out about 120 amps for $450. But what we actually USE in the car is a homebrew DC-DC converter I made for less than $200 using some Vicor DC-DC converter bricks purchased on eBay for $20 each. We have one 400 watt 12.6 vdc converter to replace the battery providing DC power all the time. It's fanless, and so doesn't eat much of our pack energy when the car is just sitting. But when you open the door and start doing stuff, it provides the "heartbeat" power to begin bringing up the systems.

If you hit the START/STOP button, it powers up a second fan cooled 1500 watt DC-DC converter made of the Vicor bricks. These bricks, nominally 300 volt input, can operate quite well over the range of 180 to 380 vdc. Three of them will put out 120 amps at 12.8 vdc.

Both DC-DC converters fit nicely into the battery compartment - saving about 20 lbs of weight. On this car, I roughly calculate 50 pounds weight to an additional 1 mile range. And they can never "run down". If they can run down the 40 kW traction pack, you've let it sit a LONG time.

Sounds simple, but it's actually one of those pernicious electric car problems that never quite get solved satisfactorily. I'm pretty happy with this one.

Note that in the video, I mentioned 90K trim resistors to get 12.8 vdc output. These are the wrong values (different DC-DC converter). This one uses 140K trim resistors. I don't care if they are 1% or not. I just use a good ohmeter and manually match these as closely as possible by picking them out of a band of 100 of them. It is kind of important they be very close to the same value if you want the three bricks to share nicely.

Also not mentioned was any kind of input fuse. You really should have a small 10 amp fuse on the +375 volt input. If one of the bricks goes berserk, it will disconnect you from the pack voltage.

What else? Well, we have started playing with chargers and charging. Like the Brusa 412, the Brusa NLG-513 is available for Euros, which has caused the price to go up in dollars. It's now $3,900. That's a lot for a charger that will put out 8.5 amps at 400 volts. We were going to use TWO of them to get 17 amps at 400 volts. That would let us charge the 40 kW pack in about 6 hours. An acceptable performance. But $7800 for chargers?

We're not finding an inexpensive solution here frankly. A 375 volt system charged to 392 volts requires a charger that will put out 400 volts or so. That's a pretty rarified area for chargers. And the ones that can do it, are all pretty much limited to 3.3-3.6 kW. That implies a 12 hour charge time. That's probably too long to really be comfortable. If I roll in at Midnight and can't really count on a full charge until 10:00Am or worse noon, that's not optimum.

But I just haven't found a charger that will "finish" off a pack like the Brusa. It's Constant Voltage (CV) algorithm is pretty accurate. And the programmability lets me kind of sneak up on the final charge, finishing off very gently at low power levels.

A LOT of the charger manufacturers are very closed about their "programmable" chargers. We had a fascinating conversation with DeltaQ, who don't do high power or high voltage anyway. But they program "charge curves" that you can "select from." We asked them why they just don't let us program the charge curves ourselves. They are scared to death of being held liable for damage to batteries. Oh well....

So what we're looking at is a combination of things. We've been wanting to play with faster charging techniques. We really don't have a NEED to charge very quickly. But purportedly, these cells can be charged at 3C or 300 amps. They can certainly be charged at 1C or 100 amps which would let us charge in an hour. So I've been planning on how to do that. Nothing available will charge at 100 amps.

So this week we wired the car with a couple of 1 AWG short cables to the pack terminals. These cables are terminated with Tweco welding cable quick disconnects. These are great little devices for connecting high power cables. The male "pin" which is about 3/8 inch in diameter, has a little cam in it. A matching cam on the female plug allows you to insert this very large terminal pin, and twist it to lock it. The cam forces the two faces together providing an excellent very low resistance current path. And the connection is basically "locked". If you twist it the other way, the thing pops apart very easily. I love these things and vastly prefer them to the Anderson Connectors traditionally used for batteries. I've had several "incidents" with Andersons and do NOT like to use them, although some equipment comes wired with them already and what's to do?

So the car is wired with terminals that would allow cable connections that would carry 400 vdc at 300 amps. All I have to do is come up with that amount of power somewhere.

Long term, the obvious answer is a "mother" battery pack of 400 vdc. This could charge all the time. Pull the car in, connect the mother pack to the car, and it will dump a LOT of power into the pack. That can get you going again. Or you can then use the single Brusa to "finish charge" the pack.

An intermediate step is a large, high powered charger. They're not cheap either, but can be kept in the garage and used on multiple vehicles. We just received serial number 3 of Manzanita's PFC-75 charger. They call this a 75 amp charger. At 400 vdc it cannot deliver 75 amps. It can DRAW 75 amps at 240 vac, purportedly. At 400 vdc it can deliver about 38 amps dc charge. But that's double the 17 amps we would get from TWO Brusas.

The Brusa charger is isolated. The Manzanita is NOT isolated. You don't want one of these feeding into the other. But we think we can plug them BOTH in and do something kind of cool. If we can set the voltage cutoff on the Manzanita so that it bulk charges up to a certain level and then shuts down, the Brusa can then continue to do the finish charge. At 38 amps from the Manzanita, and 8.5 amps from the Brusa, we should be looking at 46.5 amps and a total charge time of about 2 hours. This is also the IDEAL charge rate of 1/2 C for these cells.

In next week's show I'm going to revue the pro's and cons of this $4400 Manzanita. It's very, very good, and very bad at the same time.

Long term, I see a mother battery bank, kept charged by the Manzanita, and then a charge function using both the Manzanita and the battery bank in less than an hour. I'd like to package all of this in another vintage gas pump type package with cables and so forth. Ultimately, we would combine all of this with a higher voltage PWM controller and some meters to let you "dial in" exactly the voltage and current you want to charge at to do multiple different vehicles conveniently.

In the meantime, we don't have a drive train, and we can't drive the car. That lets us charge once in a row, and that's not a real good test. We had previously installed the 4kW electric water heater we will use for heat in the Mini Cooper. This week we wired it up to the traction pack voltage and the 12 vdc control and pump supply. The Mini just expects constant hot water from the engine and really doesn't have any control for this. It MONITORS the temperature to help with the air mixing function, but it doesn't do anything to control it. Worse, it's kind of an integrated air conditioning/heating system and I can't really find any function that is sufficiently analogous to use to turn on the water heater. However I approach it, there would be times when the water heater is on and drawing 10 Ah per hour (10% of our pack capacity) when I don't need heat, or not turned on at all when I do.

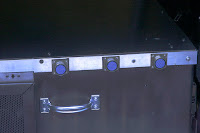

So we had to go to a manual solution. We installed a three switch control panel in the center console that simply switches 12vdc from our new fuse block in the engine compartment to 3 different systems. The first system will be the 4 kW water heater. The other two are spare for the moment. I rather believe we'll have other areas where we fail to automate.

So to turn on the heat, you have to also turn on the heated water. Flip a toggle switch. They light up with little LED's on the end of the toggle. And of course flip it off when you don't need heat. I think this will all work pretty well actually.

So that gives us a LOAD. It's a bit slow, at 10Ah per hour. But I do now have a way of draining the traction pack now so we can play with the charging process.

Jack Rickard

We had done a video on the EVision installation. What we didn't show was all the wires we got in wrong. We spent a day troubleshooting this and finally got everything hooked up correctly. The display mounted in the air vent is absolutely gorgeous, and now gives me a way to monitor energy into and out of the pack.

This week's show is largely about DC-DC converters. Our pack voltage is nominally 375 volts. We charge to 392, but as soon as you remove the charger, it settles to about 375. The Mini Cooper is an absolutely AMAZING device. Normally, automotive manufactures add "features" that they can upsell to customers at additional cost. The BMW Mini Cooper is quite different. It has DOZENS of "hidden" features you will never know are there.

For example, the engine control unit, termed a DME in BMW parlance, has a power management system. A fuseblock just off the battery terminal allows it to monitor battery voltage, battery CURRENT and battery temperature. There are several levels of ON in this car. There is unswitched power to run the courtesy lights, remote control radio, power windows, doorlocks, etc. Then if you put the remote in it's little dock, the CAS computer starts waking things up. The system has a body K CAN bus, a power train PT CAN bus, a MORE bus for the radios, etc. And it brings up power in different "levels" or "terminals".

If the engine is running, and the battery starts to provide a lot of 12 vdc power, the DME can actually note this, and will very subtly increase engine RPM to increase alternator output.

This is just one example. The heated seats are another. They contain temperature monitors and when you turn on the heated seats, they don't just switch 12 vdc to some heaters. They monitor the switch at three levels, and the temperature monitor, and power the resistive heating elements with separate pulse width modulators.

This theme is repeated throughout the car. There are dozens of hidden items. The air conditioning and heating has temperature sensors at two points in the car, a SOLAR sensor to detect sunlight gain, temp sensors on the heat exchanger and air conditioning evaporator, etc. etc. etc. How much heat or air conditioning is not exactly a function of hi/med/lo on this car. It has a separate computer just to calculate how much hot/cold/fresh air to mix. VERY advanced. And hard for us country bumpkins to deal with in a way. But WHAT A CAR.

In any event, in this weeks show we look at some options for replacing the battery and alternator for this car with a pair of DC to DC converters. We talk about the Brusa model 412. This monster puts out 1725 watts of power (125 amps at 13.8 vdc from 375 vdc input). Very capable. But the falling dollar has likely put it out of reach of most at $3200.

We do describe how to combine three Kelly 125 vdc DC-DC converters to put out about 120 amps for $450. But what we actually USE in the car is a homebrew DC-DC converter I made for less than $200 using some Vicor DC-DC converter bricks purchased on eBay for $20 each. We have one 400 watt 12.6 vdc converter to replace the battery providing DC power all the time. It's fanless, and so doesn't eat much of our pack energy when the car is just sitting. But when you open the door and start doing stuff, it provides the "heartbeat" power to begin bringing up the systems.

If you hit the START/STOP button, it powers up a second fan cooled 1500 watt DC-DC converter made of the Vicor bricks. These bricks, nominally 300 volt input, can operate quite well over the range of 180 to 380 vdc. Three of them will put out 120 amps at 12.8 vdc.

Both DC-DC converters fit nicely into the battery compartment - saving about 20 lbs of weight. On this car, I roughly calculate 50 pounds weight to an additional 1 mile range. And they can never "run down". If they can run down the 40 kW traction pack, you've let it sit a LONG time.

Sounds simple, but it's actually one of those pernicious electric car problems that never quite get solved satisfactorily. I'm pretty happy with this one.

Note that in the video, I mentioned 90K trim resistors to get 12.8 vdc output. These are the wrong values (different DC-DC converter). This one uses 140K trim resistors. I don't care if they are 1% or not. I just use a good ohmeter and manually match these as closely as possible by picking them out of a band of 100 of them. It is kind of important they be very close to the same value if you want the three bricks to share nicely.

Also not mentioned was any kind of input fuse. You really should have a small 10 amp fuse on the +375 volt input. If one of the bricks goes berserk, it will disconnect you from the pack voltage.

What else? Well, we have started playing with chargers and charging. Like the Brusa 412, the Brusa NLG-513 is available for Euros, which has caused the price to go up in dollars. It's now $3,900. That's a lot for a charger that will put out 8.5 amps at 400 volts. We were going to use TWO of them to get 17 amps at 400 volts. That would let us charge the 40 kW pack in about 6 hours. An acceptable performance. But $7800 for chargers?

We're not finding an inexpensive solution here frankly. A 375 volt system charged to 392 volts requires a charger that will put out 400 volts or so. That's a pretty rarified area for chargers. And the ones that can do it, are all pretty much limited to 3.3-3.6 kW. That implies a 12 hour charge time. That's probably too long to really be comfortable. If I roll in at Midnight and can't really count on a full charge until 10:00Am or worse noon, that's not optimum.

But I just haven't found a charger that will "finish" off a pack like the Brusa. It's Constant Voltage (CV) algorithm is pretty accurate. And the programmability lets me kind of sneak up on the final charge, finishing off very gently at low power levels.

A LOT of the charger manufacturers are very closed about their "programmable" chargers. We had a fascinating conversation with DeltaQ, who don't do high power or high voltage anyway. But they program "charge curves" that you can "select from." We asked them why they just don't let us program the charge curves ourselves. They are scared to death of being held liable for damage to batteries. Oh well....

So what we're looking at is a combination of things. We've been wanting to play with faster charging techniques. We really don't have a NEED to charge very quickly. But purportedly, these cells can be charged at 3C or 300 amps. They can certainly be charged at 1C or 100 amps which would let us charge in an hour. So I've been planning on how to do that. Nothing available will charge at 100 amps.

So this week we wired the car with a couple of 1 AWG short cables to the pack terminals. These cables are terminated with Tweco welding cable quick disconnects. These are great little devices for connecting high power cables. The male "pin" which is about 3/8 inch in diameter, has a little cam in it. A matching cam on the female plug allows you to insert this very large terminal pin, and twist it to lock it. The cam forces the two faces together providing an excellent very low resistance current path. And the connection is basically "locked". If you twist it the other way, the thing pops apart very easily. I love these things and vastly prefer them to the Anderson Connectors traditionally used for batteries. I've had several "incidents" with Andersons and do NOT like to use them, although some equipment comes wired with them already and what's to do?

So the car is wired with terminals that would allow cable connections that would carry 400 vdc at 300 amps. All I have to do is come up with that amount of power somewhere.

Long term, the obvious answer is a "mother" battery pack of 400 vdc. This could charge all the time. Pull the car in, connect the mother pack to the car, and it will dump a LOT of power into the pack. That can get you going again. Or you can then use the single Brusa to "finish charge" the pack.

An intermediate step is a large, high powered charger. They're not cheap either, but can be kept in the garage and used on multiple vehicles. We just received serial number 3 of Manzanita's PFC-75 charger. They call this a 75 amp charger. At 400 vdc it cannot deliver 75 amps. It can DRAW 75 amps at 240 vac, purportedly. At 400 vdc it can deliver about 38 amps dc charge. But that's double the 17 amps we would get from TWO Brusas.

The Brusa charger is isolated. The Manzanita is NOT isolated. You don't want one of these feeding into the other. But we think we can plug them BOTH in and do something kind of cool. If we can set the voltage cutoff on the Manzanita so that it bulk charges up to a certain level and then shuts down, the Brusa can then continue to do the finish charge. At 38 amps from the Manzanita, and 8.5 amps from the Brusa, we should be looking at 46.5 amps and a total charge time of about 2 hours. This is also the IDEAL charge rate of 1/2 C for these cells.

In next week's show I'm going to revue the pro's and cons of this $4400 Manzanita. It's very, very good, and very bad at the same time.

Long term, I see a mother battery bank, kept charged by the Manzanita, and then a charge function using both the Manzanita and the battery bank in less than an hour. I'd like to package all of this in another vintage gas pump type package with cables and so forth. Ultimately, we would combine all of this with a higher voltage PWM controller and some meters to let you "dial in" exactly the voltage and current you want to charge at to do multiple different vehicles conveniently.

In the meantime, we don't have a drive train, and we can't drive the car. That lets us charge once in a row, and that's not a real good test. We had previously installed the 4kW electric water heater we will use for heat in the Mini Cooper. This week we wired it up to the traction pack voltage and the 12 vdc control and pump supply. The Mini just expects constant hot water from the engine and really doesn't have any control for this. It MONITORS the temperature to help with the air mixing function, but it doesn't do anything to control it. Worse, it's kind of an integrated air conditioning/heating system and I can't really find any function that is sufficiently analogous to use to turn on the water heater. However I approach it, there would be times when the water heater is on and drawing 10 Ah per hour (10% of our pack capacity) when I don't need heat, or not turned on at all when I do.

So we had to go to a manual solution. We installed a three switch control panel in the center console that simply switches 12vdc from our new fuse block in the engine compartment to 3 different systems. The first system will be the 4 kW water heater. The other two are spare for the moment. I rather believe we'll have other areas where we fail to automate.

So to turn on the heat, you have to also turn on the heated water. Flip a toggle switch. They light up with little LED's on the end of the toggle. And of course flip it off when you don't need heat. I think this will all work pretty well actually.

So that gives us a LOAD. It's a bit slow, at 10Ah per hour. But I do now have a way of draining the traction pack now so we can play with the charging process.

Jack Rickard

Weekly Shows

Brain wants to be on TV it looks like. He has pestered me for a month or so now to do a WEEKLY video news show on electric vehicles and conversion issues. I once did 12 years with a MONTHLY magazine deadline and it can be wearing. How we could do a WEEKLY magazine, and in video no less, I cannot imagine.

So we shot one, on a Friday. The next Friday he's gone to the Citadel to see a football game. Oh well. How WEEKLY it will be remains to be seen. Picture an ever so often WEEKLY video.

But after doing two, I confess I like the format. We can weave in some of what we're doing on the Mini Cooper. But we purchase, test and evaluate a lot of EV components in my pathologically curious but not very thrifty fashion. And we probably should share the information. And it will give me a chance to editorialize in the ranting and raving fashion I was accustomed to in the magazine business.

We'll feature the current release at http://evtv.me on the main page. But I've created an archive page designed to present all past shows with a bit of description of what was covered in each of them.

I am convinced Internet video is the future. The cameras made a huge step function leap in 2009. The editing software made a huge step-function leap in 2009. YouTube now consumes as much bandwidth as the entire Internet did in 2002. And the carriers are quietly becoming resigned to the fact that much more bandwidth is going to be necessary with video even swamping cellular phone traffic. But broadband keeps on. Six months ago, I tried to get 2 Mbps upstream/ 2 Mbps downstream from the cable company at $160 per month. They could NOT deliver it. I was getting 1.25 Mbps upstream and 12.75 Mbps downstream and had them yank it.

Two weeks ago they called offering 8 Mbps downstream and 2 Megabits upstream for $119 per month. I explained to the sales lady that they couldn't do PART of that and until they could deliver what they were offering, I wasn't interested. She said she was sure they could do it.

She "checked with engineering" and came back a couple of days later with a guarantee that if it didn't perform, they'd cancel it no harm no foul - and no "who's on first" like I endured last time. I agreed.

I'm getting about 1.85 upstream and 8.4 Mbps downstream. Close enough.

So what I'm seeing is a huge increase in camera capabilities, editing capabilities, and bandwidth in support of basically what consumers have demanded the Internet be - video.

We've located and licensed some great player software and hooked up with Amazon's S3 storage service and their Cloudnet network. And we're continuing to work on the model. What this means is we can offer a LOT better video than YouTube, and without the 10 minute limits. We're doing 1280x720 HD video with H.264 compression (NOT FLASH). And with Amazon's Cloud this is spotted on servers all over the U.S., Europe, and Asia. What this means is that the system automatically routes you to the closest edge server to download the video files, typically 2 Gigabytes each.

This lets us do long videos of an hour or an hour and a half, at quite acceptable resolution. And unlike YouTube, you're welcome to download them and distribute them as widely as you care to.

We're also experimenting with clickable ads overlaying the videos. These only work online at this point. But if you see a green panel pop up, you can click on it to go to that web site for more information. The video will pause right where you were at, and if you close the new tab or window, you're right back where you were in the video.

I think these new video over Internet models are very exciting. A program isn't ON at a particular time. It's ON at YOUR time discretion. Yes, we have a weekly show. You can watch 3 weeks ago just as easily as the current one. YOU call the tune. I think that's cool.

Downside? Well the YouTUBE model is based on YouTube paying the bandwidth charges. In theory, they make it up with ads. In reality, they've never caught up. They spend twice as much on bandwidth as they take in in ad revenues. So they beat up thte people that are providing content. You can't post links to sites off their service (is that childish or what. We'll FORCE you to stay here? On the Internet?). They limit videos in size, resolution, and length. And they splash stupid out of context ads all over your page. It's actually an abusive horror as far as I'm concerned.

EVERYONE told me no one wants to watch a video over 5 minutes in length. I, in contrarian fashion, cannot imagine anything useful or informative that I would find in a video in LESS than five minute length. So we're doing long videos. You can watch part of them, all of them, or go to YouTube and watch a 3 year old get his finger bit by his baby brother. In any event, you're in control.

The downside is that I get to pay for the bandwidth. It's running about 30 cents each time one of you guys watch a full video. So I'm hoping at some point all of this comes together and makes sense. For now, it's all an experiment in the tools and models of a new Internet for me. As I watch traditional music distribution, movie distribution, and advertising models collapse in front of me, the question comes up - what comes out of all this and where does it go?

I believe it is a kind of interactive video web with links to both ads, product placements, and information. Whoever masters that medium in the future wins.

One of the back burner projects is to share the technique. There are actually a lot of pretty serious "Indy" video producers out there for which the current free models of YouTube et al simply aren't working. We may pick out a few and show them how to do this like big boys.

Jack Rickard

So we shot one, on a Friday. The next Friday he's gone to the Citadel to see a football game. Oh well. How WEEKLY it will be remains to be seen. Picture an ever so often WEEKLY video.

But after doing two, I confess I like the format. We can weave in some of what we're doing on the Mini Cooper. But we purchase, test and evaluate a lot of EV components in my pathologically curious but not very thrifty fashion. And we probably should share the information. And it will give me a chance to editorialize in the ranting and raving fashion I was accustomed to in the magazine business.

We'll feature the current release at http://evtv.me on the main page. But I've created an archive page designed to present all past shows with a bit of description of what was covered in each of them.

I am convinced Internet video is the future. The cameras made a huge step function leap in 2009. The editing software made a huge step-function leap in 2009. YouTube now consumes as much bandwidth as the entire Internet did in 2002. And the carriers are quietly becoming resigned to the fact that much more bandwidth is going to be necessary with video even swamping cellular phone traffic. But broadband keeps on. Six months ago, I tried to get 2 Mbps upstream/ 2 Mbps downstream from the cable company at $160 per month. They could NOT deliver it. I was getting 1.25 Mbps upstream and 12.75 Mbps downstream and had them yank it.

Two weeks ago they called offering 8 Mbps downstream and 2 Megabits upstream for $119 per month. I explained to the sales lady that they couldn't do PART of that and until they could deliver what they were offering, I wasn't interested. She said she was sure they could do it.

She "checked with engineering" and came back a couple of days later with a guarantee that if it didn't perform, they'd cancel it no harm no foul - and no "who's on first" like I endured last time. I agreed.

I'm getting about 1.85 upstream and 8.4 Mbps downstream. Close enough.

So what I'm seeing is a huge increase in camera capabilities, editing capabilities, and bandwidth in support of basically what consumers have demanded the Internet be - video.

We've located and licensed some great player software and hooked up with Amazon's S3 storage service and their Cloudnet network. And we're continuing to work on the model. What this means is we can offer a LOT better video than YouTube, and without the 10 minute limits. We're doing 1280x720 HD video with H.264 compression (NOT FLASH). And with Amazon's Cloud this is spotted on servers all over the U.S., Europe, and Asia. What this means is that the system automatically routes you to the closest edge server to download the video files, typically 2 Gigabytes each.

This lets us do long videos of an hour or an hour and a half, at quite acceptable resolution. And unlike YouTube, you're welcome to download them and distribute them as widely as you care to.

We're also experimenting with clickable ads overlaying the videos. These only work online at this point. But if you see a green panel pop up, you can click on it to go to that web site for more information. The video will pause right where you were at, and if you close the new tab or window, you're right back where you were in the video.

I think these new video over Internet models are very exciting. A program isn't ON at a particular time. It's ON at YOUR time discretion. Yes, we have a weekly show. You can watch 3 weeks ago just as easily as the current one. YOU call the tune. I think that's cool.

Downside? Well the YouTUBE model is based on YouTube paying the bandwidth charges. In theory, they make it up with ads. In reality, they've never caught up. They spend twice as much on bandwidth as they take in in ad revenues. So they beat up thte people that are providing content. You can't post links to sites off their service (is that childish or what. We'll FORCE you to stay here? On the Internet?). They limit videos in size, resolution, and length. And they splash stupid out of context ads all over your page. It's actually an abusive horror as far as I'm concerned.

EVERYONE told me no one wants to watch a video over 5 minutes in length. I, in contrarian fashion, cannot imagine anything useful or informative that I would find in a video in LESS than five minute length. So we're doing long videos. You can watch part of them, all of them, or go to YouTube and watch a 3 year old get his finger bit by his baby brother. In any event, you're in control.

The downside is that I get to pay for the bandwidth. It's running about 30 cents each time one of you guys watch a full video. So I'm hoping at some point all of this comes together and makes sense. For now, it's all an experiment in the tools and models of a new Internet for me. As I watch traditional music distribution, movie distribution, and advertising models collapse in front of me, the question comes up - what comes out of all this and where does it go?

I believe it is a kind of interactive video web with links to both ads, product placements, and information. Whoever masters that medium in the future wins.

One of the back burner projects is to share the technique. There are actually a lot of pretty serious "Indy" video producers out there for which the current free models of YouTube et al simply aren't working. We may pick out a few and show them how to do this like big boys.

Jack Rickard

Thursday, October 8, 2009

Sky Energy's Blue Sky Cell Data

We're nearing completion of the battery box installation on the 2009 Mini Cooper Clubman. This pretty much had us down in the floor wrestling in the mire. Not sure just how much video will be useful. I have posted a new video with the gas tank boxes, but the other two - I can see where we could have shot more, and I can see where a lot of what we did shoot isn't going to survive the editing process. There is just so much of drilling and riveting anyone can be expected to watch on purpose.

As noted earlier, I had decided to wire all the cells to amphenol plugs and build a test set to allow me to balance cells manually. I don't know why I've caved on this. SO MANY people have warned me so emphatically that without a BMS I am TRULY among the lost of the lost and horrible things will happen to the entire Midwest if I don't get with the program. So I've spent hours and hours wiring these things up and cell balance, at least initially, even though we have 112 of them this time, just doesn't seem to be a problem.

After the 107 mile run in the Speedster, I was certain I would need to trim them up with a little charging here and discharging there to bring em in line. Despite the fact that I had run the Thundersky's down to 2.8-2.9 vdc - over the knee of the discharge curve, all the cells were REMARKABLY close. THIS BALANCING ISSUE IS BOGUS. I've put 5000 km on this car and it isn't a problem. I've overcharged, overdishcarged, and done everything to these batteries to TRY to kill them and/or induce some imbalance without actually draining a cell or overcharging a cell myself to prove it could be done. I cannot discern real world data with a huge investment in test equipment to support the theory, much less what appears to have become a religion, about LiFePo4 cell balancing issues. I hear you. I have listened for over a year. But when I look at the meter, there's something wrong between what you are telling me, and what I'm seeing. I don't know what I'm missing, but there's a big disconnect here.

So I feel a bit foolish having installed about 30 unneeded pounds of 16 gage wire so I can access cell voltages without disassembling these largish battery packs. And when I cycle my Soviet Submarine wafer switch through the cells, it SURELY does get boring. They're all the same.

But I feel a little better after today. And I feel a little drained. I basically spent from noon to seven o'clock this evening standing there with a stopwatch and an Agilent 5 1/2 digit bench multimeter. I love the West Mountain Radio load system. It does nothing it purports to do, but the little bit it does, it does pretty good. It's charts are awful and it can't read a voltage if you sound it out audibly yourself. In fairness, putting a 100 amp load on a 3.3 volt cell, tiny resistances in the cables and connections just throw voltage reading out the window. You have to put a meter that ISN'T loading it, directly on the terminals. I explained this a bit in the post about the test box we built.

In any event, about all it DOES do pretty well is maintain a pretty constant current load on a battery that is changing in voltage. And it does totalize AH in reasonably accurate fashion.

We have most of our 100 Ah Blue Sky's in the car. I had done some capacity testing and they were checking out at least as good as advertised and some quite a bit better. Today we received a shipment of the larger 180 Ah Blue Sky's.

I've spent most of the past year working with THundersky's - same manufacturer really but a bit different olivine structure on the cathode. Manufacturers recommendation is to charge to 4.25 vdc, although they do mention in passing that you can extend the life of the cells by limiting this to 4.10 vdc. But the charge curve was so steep, that at about 4 volts, charging a series string, you would lose control and some of the cells would shoot considerably past 4.25 volts while others lagged. So we learned to charge to a lower voltage, kind of right at the knee of the curve where it turns up. As it turns out, you don't get much additional energy into the cells anyway after about 3.75 vdc. So we've been pretty happy there.

The discharge curve comes right back down the hill to 3.3 or thereabouts and then declines very gradually to about 3.0 vdc. After three volts, it again turns wickedly sharp downhill. Below about 2.8 vdc there is nothing there to look at but cell death. In doing the 107 mile run, I ended between 2.8 and 2.9 across the pack. Another mile would have probably been disastrous.

The Blue Sky's are spec'd, in the terse, no information really style I've come to expect from the Chinese. Charge to 3.6 volts. Discharge to 2.0 volts. That's much LOWER on the high side than the Thundersky's, and ALSO much lower on the low side, 2.0 vs 2.5 vdc. So I've been wondering what all this really means.

Today I found out. Incredibly, the Blue Sky's have an even flatter curve than the THundersky's. Worse, after the knee in the curve on either end, it is even more precipitous.

I learned this by standing there and manually measuring the voltage every five minutes while charging them at a constant 75 amps. I then let the batteries rest for 15 minutes and settle to their static voltage. And then I began discharging them at a constant 99 amp rate. The two accompanying graphs tell the tale.

In the case of the charging, the manufacturer suggests that the batteries be stored any time you are not using them at 50-60% charge. These arrived in about the right range. It took 80 minutes to fully charge them at a very constant 75 amps off a bench power supply. That sounds a whole lot like we put in EXACTLY 100 Ah into these 180 Ah cells. As soon as we put power to it, the voltage went to 3.4600 and hung like a rock for about 35 minutes. I kept rechecking my meter connection to the cell terminals, but that was the reading. At 40 minutes it finally climbed to 3.4675 and from there climbed nicely at first and then sharply to 3.59 volts. At that point, it zoomed in the next five minutes to 3.76 vdc. If you must charge to 3.6, I suggest keeping an eye on it. It takes off very fast. Much steeper than the THundersky's I think.

The corollary is they hang in there longer at the lower voltage, before taking off on this very steep climb. That's good to a point. But we have to know where to shut it off. I'm going to err on the side of caution, and realizing you don't forfeit very much this way in capacity per ride, and might gain a lot in cycle life, and call it over and done with at a more conservative 3.5. We want to get everyone into the pool and off this 3.46 plateau, but that's about it. Not much in there for us after 3.5 volts.

On a 112 cell pack, that looks like a charge voltage of 392.

I included something in this graph that I wish everyone would. In talking about batteries and pack voltages, I'm never quite sure WHICH voltage you are talking about, or asking about. We will charge to 3.5 and when the pack reaches this magic 392 volts, our charger will switch from constant current source, to maintaining the cells at as exactly 392 volts as we can muster. As the cells top off, this will require correspondingly less current. The current will taper off pretty quickly in this case - albeit much more sedately at the 10 amps the Brusa can muster at 392 volts. And when the current tapers off to some small value, an amp or so, you're really quite done charging.

When the charger cuts off, within just a few minutes, the cells leak off the surface charge, basically accumulated homeless electrons that can't quite find a Lithium Ion to mate with, and the voltage drops. I have rather loosely adopted the rather loosely bandied about term "nominal voltage" for this, but what I mean is the resting static voltage after the charge process.

So in this graph, after shutting off the power supply, I simply continued to take voltage readings every five minutes as I had been doing. As you can see, the voltage dropped in the first five minutes to 3.3853 vdc. Over the next five, it kept falling to 3.3724. But by 15 minutes it had pretty much stabilized at 3.3668 vdc. So the "nominal" voltage of a fully charged Blue Sky would seem to be about 3.36 vdc.

On the discharge side, you can see we started at that 3.36 vdc, but on applying this 99 amp load, it immediately dove to 3.156. But that's really NOT much sag on a 99 amp output - a little over 0.5C. Two tenths of a volt, across 112 cells would be a noticeable 22.4 volts however.

Again, the cell seemed painted at 3.156 for 20 minutes. It then began a long slow decline down to 3.0 volts. After 3.0 volts, there was nothing good here for us. From 3.0105 it took 5 minutes to drop to 2.9161 vdc. The NEXT five minutes took it down to 2.540 and the next 5 minutes saw it shoot past 2.0 vdc limit to 1.85 vdc. Ten minutes from 2.9161 to 1.850. That's about 16.5 amp hours, but you're welcome to them. It's less than 10% of the pack energy, and I'll just throw out some upholstery or something to get that extra range. Three volts is about the end of the line for me.

So there we have it. 3.50 vdc for a 392 vdc charge voltage. We'll be looking for 3.36 vdc nominal for about a 376 vdc operating voltage. And at 336 volts, we should be getting REAL close to the EVTV Motor Verks to belly up to the bar at the Texaco Fire Chief bar for a sip of some 240 vac stuff before going home.

And I would guess our real pack storage then is something like our NOMINAL operating voltage times our Ah rating for the cells, in this case 100 Ah which is what we put in the car. And that sounds like 37.6 kWh. Another way of looking at it is how much AC you have to put in through the charger to get there, and that would be more like a nice round 40 kWh.

In any event, it's too much for our charger. While the Brusa in the Speedster will charge it pretty handily at 25 amps per hour, it is a lower voltage - about 130 vdc charge voltage. There is no free lunch and the little Brusa can only handle so much power. If you increase the voltage to 392, that's about 3x the voltage. So to produce the same power, you have to decrease how much current you put out. And that works out to a little over 8 amps. That's about 10 hours to charge an 80% DOD pack.

Not good.

These larger packs take some strategizing. We were going to put TWO Brusas in and since they are isolated chargers, we could then do 16 amps between them. Let one drop off a little early, and the other continue to do the finish charge. Easy money. And now we're back at 5 hours.

But it surely did charge nicely at 75 amps. And almost all our charging is done at home. At 75 amps it could charge in just over AN HOUR.

But my 100 amp bench power supply only goes to about 15 volts. Same problem. Scotty, we need more power.

Well, if you recall, for the TExaco Fire Chief charging station, I ran a 100 amp 240 vac circuit underground to the front of the garage outside. And as it so happens, Manzanita has just released a 75 ampere monster charger. And it is a monster. You could never put it in a car. You would be pressed to put it in a bus. And I'm guessing it's not going to quite make 75 amps at 392 volts. But it might charge this car in a couple of hours anyway.

David Kois of EVComponents used to make some replica gas pumps. But his look like a LOT higher quality than the Sky Chief we bought on eBay. He's threatened to pull the forms out and go back into production. He has a 30s style double clock face PollyGas pump that just might be big enough for a Manzanita PFC-75. If we put a REALLY big Anderson connector to the pack in the car, say under the hood. And mounted a two cable DC rig to the Manzanita, we could hook the Manzanita to the 100 amp 240 vac, and we're in business - WHEN we're home.

A couple of issues. I don't have the pump from David. And I HATE Anderson connectors. They can be very stubborn connecting and disconnecting the larger ones, and I have burned some up. We need a heavy duty DC connector for fast charging. I have seen some quick disconnects on welding cable before. We may look into that.....

By the way, EVComponents carries the Manzanita PFC-75. I think I got serial number 3 so they're pretty new, and they are pretty proud of them - even more than the Brusa. But they put out the power.....

Jack Rickard

Saturday, October 3, 2009

New Shoes on the Speedster

Our 1957 Porsche 356 Speedster replica conversion has been getting a bit of attention lately as I posted it on eBay at auction. A lot of interest, but it remains a price sensitive market and the bids fall woefully short of both our investment in it and the reserve. But it has caused a bit of attention.

Meanwhile, I had recently found a better way to present videos on our website. This is not only better than the way we were presenting them, but significantly better (I think) than they appear on YouTube. But I also have gotten smarter on some of the tools out there to monitor what people are viewing and why (Google Analytics and Web-Stats). The interest seems to be overwhelmingly in favor of the Speedster over the Mini Cooper.

We're going to complete our Mini Cooper Project, hopefully before the end of the year. And in fact, I posted a new video today. This 1:48 minute mini-series in its own right, only covers battery selection issues, layout of battery locations, box design in general, and the construction and installation of two boxes that will be placed where the original gas tank was beneath the rear seats. Despite it's length approaching two hours, these were NOT the hardest of the boxes, by a lot. So at least two more such monsters just to cover the box design and installation.

But that's not as outrageous as it sounds. While batteries and their installation would seem to be the most straightforward issue in an electric car conversion, in actuality it is at least half the effort you will spend on the project and probably a good deal more than half on many projects.

But looking at life after Mini, I am struck by the absolute ROMANCE of the Speedster. I've just never owned a car that causes so much attention everywhere I've gone (and I had one of the first civilian Hummers ever built). There just is no head turner like it. Not a Ferrari. Not a new Porsche. Nothing.

And the attention of the viewers to the web site would seem to confirm it. The Mini makes a much more practical daily driver, and certainly has its own allure as evidenced by a strong, nearly cult like following for some 50 years. It has modern amenities such as air conditioning, bluetooth for your iPhone, heated seats, hell it has windshield wipers for the headlights. It's an all weather year round car and it is truly a GREAT little car.

But it's not a Speedster. And it can't ever be a speedster.

Anything done once is worth doing again. And in these kinds of efforts, when you get done, you ALWAYS have a list of what you might have done differently. In this case, less might have been more. Less batteries. Less range. Less weight. And maybe a less muscular, but more flexible AC drive system with regenerative braking. A little neater battery layout. And some better thought to the wiring. Not the battery and motor wiring so much, but the instrumentation and other wiring that accumulated as we solved problems. I think a second run at a Speedster could be done in much neater fashion, at signficantly less expense, and at a reasonable range of 60 or 65 miles.

But range is the hot button in this game. I don't really need it, but its an easy target. Friday, we changed the tires on the existing Speedster. It had sported some very nice 195/60R15s. Like almost everything in ICEland, the evolution has been toward ever better performing components - for ICE vehicles. But generally to LESS well performing ones for electric drive applications. Tires are a good example.

We looked at the new "low rolling resistance" tires from Michelin, BF Goodrich and others. And we noticed a curious thing, we could do better than they were doing by going retro on the tires.

Briefly, our 195/60R15's are NOT stock tires from Special Editions Ltd. These tires are "sport" tires with a wider tread (195 mm instead of 185 mm) and a lower profile. The 60 refers to the ratio of tread width to sidewall height - the distance from the rim to the tread. So the tires we had were 195 millimeter wide, and 60% of that or 117 mm in the sidewall. They were also a relatively soft sticky rubber to increase grip and traction, all the things you want to hold those curves when grossly overpowered by a 180 hp CB Performance engine.

Well, the problem is "grip" and "traction" are antithetical to rolling resistance. If you want to decrease rolling resistance, you go to a NARROWER tread, higher tire pressures, and a larger diameter. Think of the very narrow hard racing tires the bicycle guys use on the Tour 'd France. There's a reason for them.

Back in the fifties and sixties, volkswagens used 165R15 tires. The sidewall ratio wasn't listed at that time, but was nominally an 80. A 165 is 30 millimeters, well over an inch narrower than the sport tires we had on. And because of the taller sidewall, larger in diameter by over an inch as well. This helps our gearing with lower RPM at higher speed in 4th gear - increasing our torque at that speed and so increasing our top speed.

The higher sidewalls provide more flex, and so a better ride. We can trade that for some more tire pressure, raising it from 40 lbs to 45 lbs.

And to wear well, the tires are made from a harder rubber. It's not as sticky, but that means it will roll with less resistance.

These original tires were bias ply. Radials do perform better in almost every respect, but we found this size in a radial. Better, or perhaps comically, depending on your taste, they were in wide whitewall. I had to try it.

This afternoon, with the new shoes and pumped up to 45 lbs, I duplicated the run we made last month of 101.85 miles on a single charge. Incredibly, it made a very significant difference. This afternoon, I drove the car 107 miles on the nose. And we were able to eliminate a small, but tricky calculation we had previously had to do on mileage because of the smaller diameter tires. These tires are very close to what the speedo is actually set up for.

This 107 miles is pretty precisely the max range. I ended the run with all cells actually quite nicely balanced at between 2.8 and 2.9 volts per cell at rest. But that's essentially it. We're over the edge of the discharge curve which drops off precipitously below 3.0 volts resting voltage. The official cutoff voltage is published at 2.5 volts. But I don't believe there are 2-4 miles range in the difference.

This was radio going full blast and some headlights on the last 15 minutes of the trip, but no heater of course. The absolute max range of this vehicle is 107 miles. But that's over 6% better than our previous best. Can tires make a 6% difference? Apparently so.

I guess I would rate the ride noticeably stiffer than the previous tires. Not bad, and not pronounced, but I could tell the difference. The sidewalls and 5 lbs were not a wash. But I think we could do 42-43 lbs very comfortably.

Actually, I LOVE the retro look on the white sidewalls.

Check out the new mini video at http://evtv.me. It's bottom row on the left.

Jack Rickard

mjrickard@gmail.com

Saturday, September 19, 2009

More Battery Boxes and a Breakout Test Box

Haven't posted for a couple of weeks. We've been busy. We're STILL working on the battery boxes.

We have the toughest one pretty much done. This is essentially a battery "module" that sits on rails where the rear passenger seat was. It slides fore and aft about 18 inches to reveal two 12 cell boxes beneath the seat area where the gasoline tank was.

There is also a 33 cell box aft where the spare tire area was below the cargo floor. By mounting it on rails, we're able to access the lower battery boxes with relative ease.

SInce it is going to be in the passenger compartment with us, there are a number of considerations we don't normally have to deal with.

First, it's fully enclosed with a lid that screws down onto the box.