Monday, August 30, 2010

Dynomometer Data Magnus Maximus

This week we celebrate departure of the Speedster Part Duh Thursday afternoon to Bremen Indiana for evaluation and examination by the pros at Special Edition Inc. It will be interesting to learn their reaction to this vehicle. A number of their customers have done electric drive installations on their rollers, and they have been very good to work with on modifications to accommodate this. This will be their first look at doing a turnkey in house. it's a daunting prospect, to approach such a thing. http://www.beckspeedster.com

Before it left, we accomplished a couple of last minute items. We DID get the EVWorks fuel gage driver waving our fuel gage needle around, and in more or less the proper direction. We also added a coolant temperature sensor to the controller chill plate and it drives the existing temp gage VERY nicely. We got lucky here.

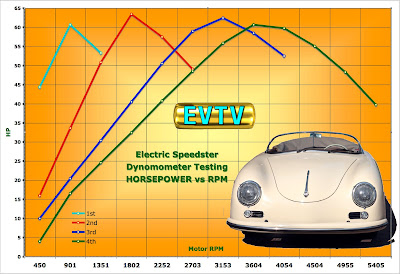

We did quite a bit of Dynomometer tests on both the original Speedster and Speedster Part Duh. Here are some of the pretty graphs images used in the video.

But we also have the full data and I'm going to make this available in Microsoft Xcel spreadsheet format for you to download and puzzle over. Two files http://media.ev-tv.me/speedsterdyno.xls and http://media.ev-tv.me/speedsterdyno2.xls

Finally, I've done a little preliminary work on an OWNERS MANUAL for Speedster Part Duh. It's not only rough, but its a long way from complete. But I thought I would post it on the Amazon server and put a link to it HERE and then just overwrite the file as I get time and update it. In this way, you can return here to this link to get the latest as it appears. It's in Microsoft Word format at the moment. Eventually it will be a PDF and we'll probably make it available for order in print on Amazon.

Subscribe to:

Post Comments (Atom)

Interesting idea with the hub motors, Jack.

ReplyDeleteThey are probably better moved out of the wheels to an inboard location that uses the CVs on stock or shortened drive shafts. There are plenty of good reasons to do this:

1. You keep the wheels and brakes as they are.

2. You keep the hub motors out of the water, debris and grime of the road.

3. You aren't shock loading the motors from potholes and curbs.

4. You aren't stressing the motor with vehicle loads.

Unless your Chinese motor builder is going to build a motor around an automotive spindle, with dual tapered wheel bearings and enough beef to pull lateral Gs and bang off of curbs, the motor has no place (literally) where the rubber meets the road.

If you don't get that, then you will be forced to fit the motor onto an automotive hub and lock it somehow, so it is only carrying rotational loads. You then need to get the stock or substitute mechanical brakes in there. No vehicle is road legal without them. Any non-weight-bearing motor and brake stack will be extremely difficult to fit on the stock rear hub (or even suspension) of the Smart. I just don't see how you have room for anything like that in the wheel well.

Pancake motors from bikes and even the new EnerTrac 600-series motorcycle motors are not designed for side loading at all. Cycles transmit few of those loads to their wheels. You need several orders of magnitude more robust of a WHEEL device, irrespective that its a motor, than anything that looks remotely like a cycle BLDC motor.

Note that my concerns have nothing to do with the torque/current/speed problem of an electric motor fixed 1:1 on the axle. That problem was best solved by DAF with their Variomatic belt drive transmission decades ago, (think snowmobile CVT on each wheel) but I digress...

There have been a lot of wheel motor projects that stopped, which is to say all of them, from Porsche 100 years ago to Bucky Fuller in the 1930s to the TM4 Mini, lots of concept cars, and now Mitsubishi appears to be the latest company to quietly kill its hub motor as the iMiEV debuts without it even on the horizon.

If you think about it, a wheel motor is actually a dumb idea. Sounds efficient and elegant, but at the end of the day the compromises are too great. Its silly to put all the road-going loads of the car into the motor, and also to put those expensive parts right down on the pavement to get banged around and soaked in saltwater. You want wear parts there. Now you have to build those wear parts into the motor, or make the motor a wear part.

Would you build the engine of an airplane into the landing gear? Into the wings? Well, Jack Northrop would, but the extreme rarity and cost of planes that do that kind of proves my point- to get ONE COMPONENT to do everything is always way, way harder and a poor compromise than having discrete, complementary systems that work better. That's why jet engines hang on pylons, and why the motors of road vehicles belong safely inside them. Just my $.02.

Still, its a cool project, and a great windmill should you manage to get someone to tip it with you. I'll be following that, and thanks again for your vigor and tenacity. I told you over a year ago I thought you should get a pinstriper to paint Rocinante on the dash of your Speedster. Its especially appropriate now that you're tweaking it. Its always going to be the best hot rod you've ever had; you know that, right? I have been to that particular rodeo.

Romance aside, doing a hub-motored Smart car puts you right back in the saddle, my friend. That's OEM country, and they have ALL died out there. Maybe they didn't need to. Have at it!

TomA

Jack, thanks for posting your user's manual, that is great stuff. More EV folks should do stuff like that.

ReplyDeleteHere are some little things I found to fix:

130 mph -- that was a dyno speed but it looks like a road speed in the document. Suggest saying "over 100 mph" or whatever the car can do instead.

60/40 rear/front --> 40/60 front/rear (the order car magazines usually use)

"Motor RPM" as a horizontal axis isn't right -- you don't have four torque peaks for the motor itself -- I assume that's dyno rpm? Suggest just leaving those out and just use the mph graphs.

Combution --> combustion

I'd add parking in neutral -- that makes it less likely someone would unexpectedly take off in gear, and also less likely the car would get towed in gear.

Suggest adding a paragraph on towing the vehicle.

You got me all fired up and cheering with the inspiring words about people needing to wake up and find out that they don't need to rely on oil anymore. That is until you said to stay away from lead/acid. But minus that one small line, I'm with you 100%! Besides, isn't locking in to lithium batteries transfering funds from the Arabs to the Chinese? :P

ReplyDeleteExcellent videos, I will never tire of watching them....

The Chinese aren't blowing up our buildings partner. I find them a much more attractive people generally, and I like what they are doing. They are trying to be like they think we are, because we used to be. Unfortunately, we're not anymore.

ReplyDeleteI did find someone making these batteries in the U.S. They don't respond to e-mails as they only want to sell to OEMs. Sigh.....

Oh, and vpoppy, STAY AWAY from lead/acid. You are only confused because you haven't done LiFePo4. It is not "the same thing." It isn't even close to the same thing. Electric cars do NOT make sense with lead, and they very DO make sense with LiFePo4. If you THINK they make sense with llead acid, I've got some GREAT news for you. You have another round of EVgrin headed your way.

Jack Rickard

Tom:

ReplyDeleteThere are some issues. Not sure I agree with what they are, but there are some issues. In any event, the interest in wheel motors never goes away, not among the OEMs and not among the EV home builders.

But we haven't even had a device to experiment with. PML Flightlink teased us for so long they changed their NAME and still no product - Protean.

We are getting "out there" enough that many of these guys are e-mailing and calling now. When I ask if it is vaporware or a real product, they always assure me it is VERY real. When I ask when they can get one onto my driveway, the stuttering and stammering begins. Not really NOW but in this case I really really mean soon. Right.......

This has the potential to help develop a 20 kw wheel motor at less than $5K per PAIR. If it will work, it probably won't be on a performance vehicle, but a Smart is small enough it just might work. A little wheel hop on an urban errand car is not a big deal. Will it last a million miles? Again, probably not Tom you're right. But it will turn what was going to be a cheap project into a fun and exciting one. I'm a little perked up about it even if it does cause a little delay.

Jack Rickard

Lol, excellent point about bombing, but really my argument is tongue-in-cheek as a lot of my lead/acid batteries have a sticker that says "Made in Mexico" anyway. More to the point, if I wasn't using lead/acid, I would not be commuting to work as lithium didn't fit in my $500 budget. And I'm pretty certain any converter out there would choose lithium over lead if money were not an issue. But the reality is that "the masses" can no more afford lithium in their conversions than they could a Tesla. Should none of them drive their cars because they use lead? What if I told you when you were working on your lead/acid Pinto "hold on, don't finish your project until I come out with these new lithium batteries", would you have stopped your conversion? The average driver in the US drives 29 miles a day, lithium is overkill. (Yes, I'm kidding again). I will be running lithium as soon as it's within my budget. Or when I find a set in someone's trash can. Whichever comes first; and at this point, both scenarios are equally likely. Until then, I have to drool at your projects.

ReplyDeleteIt is within your budget. With LA you are probably only getting 30 miles range, and if you properly size the LiFeyPo4 pack for the same range, it will not be much more expensive, and will last 4-5 (maybe 10) times as long with much better performance. Total life cycle cost for one set of Li will be far less than the multiple sets of LA that it will take to compare with. Granted there is some more up front capital required, but not as much as you might think. The problem is that once you start to change to lithium and you see how much battery space you have from your LA car you will try and fill it all with Li and it will get pretty expensive comparatively (on a volume basis).

ReplyDeleteIf have _just_ finished replacement of 480kg (1000 lbs) Lead Acid batteries to 205kg (450 lbs) of TS-LFP90AHA's and WHAT a different feeling. Even the wife thinks the car is fun to drive :)

ReplyDeleteLead Acid traction batteries has no future on the road.

For a slightly less volume I get at least 3 times the usable amount of energy and at least 5 times the life time (not validated yet). Even without the life time increase it is a better deal with lithium.

The pictures of the car will be available on my website ( http://www.citystromer.dk ) later this week.

Martin.

Since you are planning to do a revision on Speedster #1, let me vote for a Soliton1 to replace the Kelly controller. I've ordered a Soliton1 with the Evnetics throttle to go in my Bugeye Sprite conversion, and would love to follow as you blaze the trail.

ReplyDeletePictures of my lead-acid to lithium conversion are put on the web - http://www.citystromer.dk/LiFePO4-installation.html

ReplyDeleteMartin.

I generally agree with Tom A's comments on the downside of mounting the motors within the hubs and I like the suggestion of mounting them inboard using half-shafts. Besides, all that unsprung weight will ruin the high-speed handling.

ReplyDeleteIf these are DC motors, it would allow you to run them in series to form an electric differential (without the complexity of controlling AC motors in such a way); then you could switch to parallel at higher speeds. But I guess it also depends on how much space they take up compared to a 9" motor & transaxle.

Doug

Lithium has lead beat hands down for size, weight, energy density, performance, etc. But comparable in price?? Not even close. I paid $42 for my battery pack. There simply are no used lithium cells available and there won't be for quite some time. Maybe in a decade, but right now, apples and oranges for price. As long as I get to work and back without buying gas, I don't care what form my electrons come in....

ReplyDelete@vpoppy:

ReplyDeleteMy estimated cost is about 6 cents/mile (0.22 DKK/km) - the estimate is based upon a 6 years lifespan with 9300 mi/year (15.000 km/year).

The price for my lead acid batteries was (not estimated) 26 cents/mile (0.98 DKK/km).

The LA batteries was down to about 80% capacity, but was no longer able to support the car for the 25 miles (40 km) I have to work.

Martin.

You guys are making completely different points that completely agree.

ReplyDeleteIf vpoppv can get batteries for next to nothing, (and fork lift parts, contactors, etc.) and put EV miles on them, that's a good thing. He's not comparing NEW Pb batteries to Li ones, and to say that he therefore shouldn't build a beater, or even a pretty nice EV, and run it and show it to people, is silly. Its good for the movement, particularly where he can say "I made this for under $X,000."

Obviously, for a new pack, Pb batteries make no sense, and vpoppv agrees with that. Martin, you also just proved how easy it is to swap out a FLA pack for prismatic LiFePo4 cells, so there's no harm cobbling something together on golf cart batteries until you can buy a new pack.

As for this whole "beater vs. OEM-quality late-model" car thing that Jack talks about a lot, its entirely a personal preference thing, and I have to push back on this disdain for beaters. It depends a lot on where you are, geographically more than economically, really.

I live in metro New York, and I love running a daily driver old car with shabby clearcoat, some dings and a little rust. It means I don't even have to think about the constant contact and abuse my ride is getting from our very rough-and-tumble street life here, and it gives me a lower profile that is very nice at times in many communities where I go. Its not my only car, and I wouldn't pick up a client in it, but I'll never be without a well-worn, carefully maintained old sneaker of a daily use car.

We call them "station cars," since around here people commute with them to the train station. It would surprise Californians to see exactly what kind of people drive pretty non-descript older cars every day. Electrifying one of them also is a super idea. Station cars and beaters don't go very far from home, so the EV range is perfect.

An electric station car is really a perfect application, beater though it may seem. I actually think a business opportunity exists in many towns like Hinsdale, IL or Greenwich, CT to build an EV conversion shop/service garage near the train station where customers could park and charge every day, with NEV shuttle service to and from the train. Its a cool idea, and I'm quite sure it will happen.

An EV isn't yet a good only car, either, so if you're going to ADD a car to your household instead of REPLACING one, it would seem that a cheaper car is an obvious choice. Most people should be doing that with Lithium packs, it seems pointless to say floodies no place in an EV when there are cars racking up clean miles every day that would be off the road but not for Pb batteries.

Anyway, my point is you guys are actually pulling on the same end of the rope, as is Jack. Trashing beater cars running lead acid and surplus parts won't make them less workable for what they are, nor does the cost-benefit of Lithium really prove anything about this class of ride. We need the whole fleet...

TomA

Jack/Brian, I am very interested in finding out what the HPEV guys have to say in their defense regarding the disparity in HP output between the AC50 and your DC motor. Could the Curtis may have cut power for some reason? Could it be that's programmed for a less aggressive torque curve?

ReplyDeleteJR

So why don't you watch the video? We discussed all that. Bill at HPEV said this is about what they are seeing. They hope to have a new Curtis that does 650 amps in December and PERHAPS a 144v model next year.

ReplyDeleteJack

Jack, I just watched it again. Twenty mins into the video you mentioned the possible Curtis upgrade for December, great. On about min 80 you said the DC motor was running with "a little Kelly controller" yet producing more HP than the AC50. I took that as a question you were pondering about the AC50 that might have been good to bounce off HPEV. Thanks for the clarification.

ReplyDeleteJR

JR:

ReplyDeleteI do a lot of pondering. It's getting worse. One by one, I'm learning that ALL the "givens" gleaned from the body politic on the forums are proving to be questionable at best, and in some cases violently misleading.

AC vs DC, regenerative braking, battery management systems, capacitors, batteries, I feel like Charlie Brown with the football. It's making me ponder.

We LOVE the HPEVS solution with the Curtis and the AC-50. This is a relatively inexpensive package, easy to deploy and configure, sturdy, and quite reliable. It may be IDEAL for your first conversion.

Higher efficiency? Regenerative braking? It all kind of depends on what you're looking for. I know gen 1 Speedster still feels very good, and it doesn't have any of that. And I can easily add a Soliton1 or a Zilla. It is trivial, for MORE power.

Brian would do great with the AC-50. Regenerative braking gives me NEGATIVE NUMBERS. Driving style.

We're indeed looking at Netgain again for several projects. AC has had us, and the entire community, mesmerized for several years. And it remains a very interesting option.

But the nirvana promised just isn't there. Better faster simpler cheaper. I want to pick all four. And MOST of what I've been told, is just a simple refined version of bullshit, made palatable by furious and repeated typing.

The quest goes on. So we ponder. Results are results. There are no "accidents" and there are no "anomalies". They just are what they are. What they mean takes some pondering.

What always amazes me, so many opinions. So little data. Does anyone dyno their cars? I mean it IS $150 freakin dollars....

Jack

Jack Rickard

http://www.neon-john.com/EV/Crazyhorse_Pinto_HP_Torque_06AUG08.pdf

ReplyDeletehttp://www.killacycle.com/photos/index.php?album=ahdra-race-march-07&image=DynoKillaCycleRun2.jpg

Also many do 1/4 mile runs for performance comparison.

[quote]... So little data. Does anyone dyno their cars? I mean it IS $150 freakin dollars....[/quote]

Jack: I've spent a lot of time analyzing scientific data, and it appears to me that your Current Vs. Mph plot for 4th gear has an out-lier data point at 60mph. At 135A, it considerably differs from the other gear's current values for that speed as well as not being smooth WRT (with respect to) the rest of the data for 4th gear.

ReplyDeleteAs further support, I noticed that Brian (I assume in the interest of time) didn't allow much time for the current/speed to stabilize at each data point. Most of the points look pretty good, but I've noticed that on my BMW (which has an MPG gage, actually a vacuum gage calibrated in MPG) that small changes in accelerator pedal position produce large changes in indicated mpg while speed takes a long time to change.

--Dennis Van Swol--

Dennis:

ReplyDeleteYes, we noticed it as well. I asked him about it several times. It has to be an outlier. But I put in what he wrote down. Sometimes there ARE mysteries and I am very hesitant to just throw out measurements. THey are what they are. Sometimes later, it becomes apparent what you were seeing. And sometimes they are just outliers.

Jack Rickard

Don't know if you've seen this, two Enertrac motorcycle wheel motors mounted inboard to power a Miata:

ReplyDeletehttp://www.youtube.com/watch?v=VGO2t0kuVkc

http://www.enertrac.net/product.php

Might work on the Smart.

JRP3

Hi Jack,

ReplyDeleteThanks for sharing the data files.

I think the plots vs. RPM should use Motor RPM. Then all the plots overlap except for the first gear "zero" torque point. [I will email the spreadsheet back.]

To get the constant torque of 96 Nxm, I guess that you have a motor current limit of 470 amps. The 60 hp peak matches 120 Volts, I guess.

Are those values correct?

oops, typo... that is 96 ft-lbs.

ReplyDeleteThere seems to be something screwy about the current. If you divide kW by amps, you get something like 800 volts.

off the graph:

ReplyDelete45kw / 410A = 109.7V

off the spreadsheet 1, the voltage always seems to be 115v...were the current values actually measured, or just calculated?

off spreadsheet 2, the kw and current numbers definately don't match.

Jack - when the measurements were being made, was the rpm steady? or were you taking measurements on the fly?

what were you using to measure current?

was it battery current or motor current?

Matt