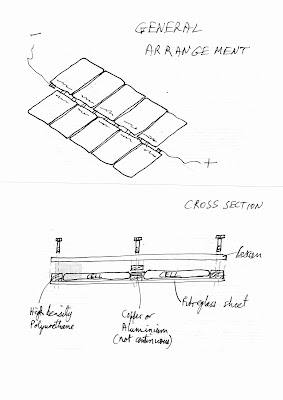

He suggested a flat pack design and while a little rough and perhaps a little obvious, we pretty much liked the idea.

We've been talking about a flat pack for a few weeks to put under a Smart Car build or to test an A123 pack under a Speedster. This concept does well enough.

I suppose we jumped the gun describing the book, but I wanted a little context for the conversation, like who he was and where he was from. The book came up. The problem is it isn't precisely released yet, so you can't have one. But it should be on Amazon soon.

The other aspect we went on with in this video at some length and probably at some tedium was the JLD404AH Intelligent AH Meter. We actually found this meter BY ACCIDENT in a box of stuff we had ordered a year ago. We more recently found this DC Voltmeter that allowed you to set relays based on voltage and we kind of designed a bottom balancing circuit out of this very simply by connecting that control relay to a contactor and a 0.1 ohm 250watt power resistor. This little "bleeder" would bleed a cell at about 30 amps until it gets down to 2.50 volts, or really whatever value you set, and then disconnect the load.

But while rooting through a box of similar meters, we found this Intelligent AH Meter version. We had never hooked it up. And it was no longer available, and worse the documentation was no longer available.

But it was a pretty similar meter and we gradually were able to piece together how to work it. incredibly, the relays could be activated by Voltage on those as well. In fact, you could tie the relays to voltage, current, ampere-hours, or time in a way that is so flexible, you really can't quite work it all out mentally. It actually lets you set TWO levels an activation threshold and a deactivation threshold kind of like a thermostat.

A thermostat? Well yee. THis is the easiest example, which is unfortunate because this device does NOT measure temperature. But let's say you wanted to turn on a heater to bring a pot of water to a certain temperate and hold it there. Wouldn't it be nice to have a relay that would run the heater. IF the water is below 100 degrees for example, it energizes, turning on the heater. When it reaches 140 degrees it reenergizes, allowing the temperature to fall. But at 100 degrees, it comes on again. In this way, it cycles but without hystereses. It has a band gap.

That's how these relays work. And you can set them on an ascending curve or descending curve. And they can work on voltage, current, amp hours, or time.

The flexibility of all this hurts the head, so I won't pursue it. But it makes it a very handy little device.

We went back to the guy we bought this from and had a couple of weeks of discussion to get him to reprise it. We ordered a dozen, and put it in the video which we released Sunday noonish.

We also put a description and a way to order on our web site online store. By Monday morning, we had sold twelve. Of course, I already had two of our dozen on the lab bench. So we're not only sold out, but scrambling to get enough to fill the current orders.

This basically illustrates the ongoing need for instrumentation. We recently reviewed Valery Mitzikhov's EMW Dashboard. It turns out this hardware isn't done by EMW at all, but rather by Dmitri Butvinik, an online impresario we've crossed swords with before. The hardware literally came apart in our hands. And now that we know where its from, the odds of fixing the 5% accuracy problem are essentially none. I played with some GOOD hall effect sensor s a year ago and found accuracy to be a devilish problem. I assumed Valery, with a Phd in Physics, had some magic sauce on this topic since they used a hall effect sensor. As it turns out, no. He has simply bitten on a Dmitri device assuming it would report accurate current. It doesn't. And it can't. In fact it's a very cheap hall effect sensor to begin with. Dmitri and his followers are big fans of cheap.

In any event, we're going to piece together this AH meter, a 12v DC-DC converter to power it with full isolation from your pack voltage, a shunt that COULD be mounted with a bit of additional work, and a Operations Manual that yours truly has cobbled together to serve as some DOCUMENTATION for this device.

The device uses a shunt. We get rather inexpensive shunts from China that are 75 mv. Let's talk a little about current measurement. Everyone KNOWS all this, and in most cases know at least part of it wrong.

Basically to measure current, the most accurate and temperature stable way to do this is with a known small value of resistance. According to George Ohm, the amount of current through a given resistance is a function of the voltage you apply. Conversely, if you measure the voltage across a known resistance, you can calculate the current flow.

To measure high current levels, you want a very LOW resistance value so you dissipate a minimum of current as heat. The power dissipated will be a function of current level, times resistance, squared. So if you have a high level of current, you must have a very low value of resistance.

In the U.S., most shunts are machined to have a resistance where the full current level will cause a voltage drop of 50mv. For example, you might have a shunt that is rated at 100Amps/50mv. That means that if you run 100 amps through it, you would read 0.050 volts or 50 millivolts across the terminals as the voltage drop across that resistance. If we take that voltage and divide it by the current 0.050/500 we get the resistance of the shunt resistor - in this case 0.0001 ohms or 0.1 milliohms. Indeed a very small value. But if accurate enough, very useful.

Chinese meters almost always specify 75mv shunts. And so we are coupling this meter with a 1000A/75mv shunt. In the meter, there is a APuH value where you enter the full scale value of current - 1000 amps. And of course it has a fixed 75 mv input.

Because of this full scale variable, we can actually use ANY shunt with this menu. What you are setting is the number of amperes to display and to count in the AH calculation when the meter measures 75 millivolts. If we had a 500A/50mv shunt for example, it would never exhibit a voltage drop of 75mv until it carried 750 Amperes. No problem. Hook it up to the meter and enter 750 as the full scale current value.

Similarly, if you had a 100A/100mv shunt you wanted to use. How many amperes should you enter for 75 mv? Well, how about 75 amperes?

There are a couple of things to keep in mind here. First, it is just a fixed value of resistance. The maximum current that can be measured is a function of the METER primarily. In other words, we don't know what this meter does with inputs above 75 mv. So you want more or less to size your shunt so you never exceed the 75 mv.

The other criteria is that the power dissipated DOES heat the shunt slightly. If you run 1000 amps through a 100 A shunt, not good. It will heat it and that will affect accuracy and too much heating and the accuracy goes off permanently. But it is NOT precisely a problem to run 2000 amps through a 1000 amp shunt, or 1000 amps through a 500 amp shunt briefly. We just don't' know exactly what the meter is going to do with the information.

The other proviso is that the LOWER you go the more accurate you become. There is no point using a 1000 amp shunt in a buggy that will never do more than 200 amps. The scale is 75 mv to 1000 amps and so 1 mov of change in voltage represents 13.33 amperes. At a 300 amp shunt, each millivolt represents 4 amperes so you have a much more accurate scale, and you're not going over 300 amperes anyway.

Similarly, the 75 mv shunts are more accurate, all other things being equal, than the 50 mv shunts. You are simply using a wider voltage drop to represent the same change in current.

The EV community has faced a real challenge in finding current measurement and particularly kWh or AH accumulator/counters sized for our use. The only other market for such devices, aside from nuclear power plants, are solar power systems. ANd they tend to be 50 amp and 48v scale items. Similarly, some attention is paid by large boat and recreational vehicle owners. BUt again, 48v and 50amp or 100amp is pretty much the game there.

And so if you want to accurately measure 500 or 1000 amps and you have a pack voltage of 150 or 250 volts, there is really not much out there to find in the way of generic measurement devices.

The ability to measure 50 mv or 75 mv is actually chip based. There are some phenomenal operational amplifier chips out there to do this and have been for many years. The problem is that they are now ENTIRELY surface mount devices. I cannot find one that will measure both directions and provide a useful output in a larger chip format. And I cannot SEE much less solder SMT devices.

Hall effect devices CAN output higher values such as 0-5v or 4-20ma or even 0-10v that can be read with standard A/D circuits in multicrontroller devices such as Arduinos. But they become quite nonlinear outside of their defined range, and it is quite hard to find the zero point, even with temperature compensation. And so at these scales where we are charging at 25 amps and driving at 1300 amps and need to be able to measure both accurately, that can be difficult to do with hall effect devices. And not possible at all with undersized inexpensive ones.

We have used the Xantrex device for several years. It is kind of pricey at $250-$275. I cannot SEE the display in any lighting conditions. And the little terminal board in the back is very difficult to poke a wire into and get it to stay put. But we've lived with it. THe JLD404AH is the first meter I've found that does what I want, allows control based on AH, and that I can read.

But given the immediate dozen sales, I'm guessing we need to keep looking. Apparently, we are NOT the only people looking for instrumentation.

We'll try to expedite all current orders and get new stock in soonest.

Jack Rickard