Monday, August 30, 2010

Dynomometer Data Magnus Maximus

This week we celebrate departure of the Speedster Part Duh Thursday afternoon to Bremen Indiana for evaluation and examination by the pros at Special Edition Inc. It will be interesting to learn their reaction to this vehicle. A number of their customers have done electric drive installations on their rollers, and they have been very good to work with on modifications to accommodate this. This will be their first look at doing a turnkey in house. it's a daunting prospect, to approach such a thing. http://www.beckspeedster.com

Before it left, we accomplished a couple of last minute items. We DID get the EVWorks fuel gage driver waving our fuel gage needle around, and in more or less the proper direction. We also added a coolant temperature sensor to the controller chill plate and it drives the existing temp gage VERY nicely. We got lucky here.

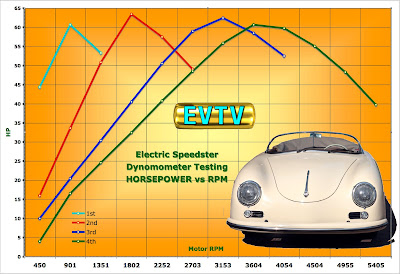

We did quite a bit of Dynomometer tests on both the original Speedster and Speedster Part Duh. Here are some of the pretty graphs images used in the video.

But we also have the full data and I'm going to make this available in Microsoft Xcel spreadsheet format for you to download and puzzle over. Two files http://media.ev-tv.me/speedsterdyno.xls and http://media.ev-tv.me/speedsterdyno2.xls

Finally, I've done a little preliminary work on an OWNERS MANUAL for Speedster Part Duh. It's not only rough, but its a long way from complete. But I thought I would post it on the Amazon server and put a link to it HERE and then just overwrite the file as I get time and update it. In this way, you can return here to this link to get the latest as it appears. It's in Microsoft Word format at the moment. Eventually it will be a PDF and we'll probably make it available for order in print on Amazon.

Thursday, August 26, 2010

The Quiet Drive

This week we start to wrap up the Speedster Part Duh and send it off to Special Editions Inc. in Bremen so they can have a look at what we've wrought.

We did something a little unusual in the video. We have found a way to do "pretty good" audio in a windy convertible. And we did a drive in the Speedster. In professional television land, which by the way we are no part of and do not want to be confused with, there is a concept called "dead air". This is where your chippy blond chick forgot her lines or a guest says something shocking and nobody talks for awhile. It is considered a Television faux pas as you need to hear some idiot yacking at every possible moment. If nothing else, cut to commercial.

The Speedster DOES make some noise. The tranny is pretty noisy as we use Redline ATF synthetic in it to minimize friction - a very lightweight oil for a transaxle. We also have a pump for the cooling system and two fans going. But it still fails to produce the roar of a real speedster. That lets you hear a lot in the world and it is one of the advantages of an EV.

So we filmed a drive. But instead of trying to fill it with yack yack, which most of you have heard from me before anyway, we just drove the car. The effect is interesting. You may find it very boring. But you will hear what I hear when I drive it, unless I've got my iPhone going through the stereo.

We have had some last minute successes before shipping. I added a very ordinary automotive coolant sensor to the chill plate and connected it up to the temperature gage on the Speedsters original Combi gage. Incredibly, it sorta kinda worked. I swapped it out from a 250 degree model to a 220 F model and now it works very well.

We tapped a hole in the chill plate and ran some threads in it. Screwed in the sensor. You have to ground the chill plate. And you connect the green wire in the engine bay to the sensor. Incredibly, the center of the gage is 75C. At 85C, which is when our controller goes into current limit, shows about 3/4 gage. At normal 45-55C, it is at the bottom. I am just delighted.

In this episode of the video, we tried the EVWORKS fuel gage driver. I didn't see much how this thing could work for us. And initially, it sure enough didn't. But we played around with it and did get it to move the needle. The problem was that it was moving it BACKWARDS. When the car was fully charged, the gage showed empty. And as you drove the car, it moved toward full. Interesting, but hardly useful.

We reversed polarity of the hall effect sensor, thinking we could charge to full, and discharge to empty that way. Good thinking, but it didn't appear to work.

Well, we don't call it part DUH for nothing. DUH. We had it on the 2/0 cable to the rear of the car that does in fact drive it. But the charge cable connects to the negative terminal block at the same place the cable does. We were charging AROUND the device. When we the smaller charging wire back through the sensor, IT WORKED!

It's a little bizarre and this product needs some further work, but I'm astounded. The parts count on it is nothing. And it more or less accurately drives our fuel gage.

Here's the problem. You have to fully DISCHARGE the car. Then flip off the maintenance switch and back on to reset the fuel gage driver. Then charge the car. It will read full when you get done charging. Then as you drive, it moves toward empty.

And here's the other problem. If you shut off the maintenance switch to do like, maintenance for example, you've just reset the fuel gage driver and have to go over the entire tedious procedure again. NOT what I want actually. But it is very neat that this thing does sorta/kinda drive this old style gage.

I'm attaching the latest version of our Control and Instrumentation schematic.

Eric Kriss has received his Porsche Speedster kit from Special Editions and is starting a project. Kriss played piano on a Grammy-nominated blues album, later founded a record company and still later co-founded private investment firm Bain Capital. He also started a healthcare company, directed the financial rehabilitation of two Massachusetts cities and, under then-Gov. Mitt Romney, helped balance the state budget and restructured its turnpike administration after a tunnel roof collapse.

But you can find what he's REALLY about at http://krissmotors.com. He's a veteran kit car guy with a Cobra and a Saab Sonnet done and done. This will be his first electric.

Eric is also the guy who posted our index to the shows if I don't disremember this all correctly.

Enjoy.

Jack Rickard

Friday, August 13, 2010

New Project

I finally got a Friday video up on Friday. This week we talk about the fix for our Mini Cooper Clubman air conditioning (many thanks Marcus Siegert) - a simple high current diode on the positive input.

We also introduce our latest project - a 2008 Smart For Two and introduce you to a new drive system, the PowerpAC30 from Elektro Vehicles Europe with their 30kw AC motor. We'll be using this system in the Smart project. We think we can put together a nice urban electric vehicle with 50 mile range for less than $25,000.

Enjoy.

jack Rickard

We also introduce our latest project - a 2008 Smart For Two and introduce you to a new drive system, the PowerpAC30 from Elektro Vehicles Europe with their 30kw AC motor. We'll be using this system in the Smart project. We think we can put together a nice urban electric vehicle with 50 mile range for less than $25,000.

Enjoy.

jack Rickard

Thursday, August 12, 2010

Speedster Part Duh Performance Testing

We completed some initial performance testing yesterday on Speedster Part Duh. We had rather carefully spec's a very different transaxle for this version in an attempt to get all four gears in the game in an attempt to duplicate the driving characteristics of the original Speedster, and perhaps of course improve upon them where able.

The result is the car shifts smoothly through all four and all the ratios feel like they belong there and are needed. With the very low mounted battery weight and stiffer springs, the car drives very flat and there is no real hint of oversteer on curves.

In acceleration testing, we wanted to compare the acceleration times to various speeds with the original 1957 Porsche 356A with the 1600cc engine. For me, this is the definitive Porsche Speedster.

We took the original data from the book Porsche 356, Driving in its Purest Form by Dirk-Michael Conradt. This is an excellent production history of the Porsche 356 in all variants.

The results are given below. With the new transaxle gearing, we compare very favorably through all four gears.

Conditions were 96F, wind calm on flat road.

Jack Rickard

The result is the car shifts smoothly through all four and all the ratios feel like they belong there and are needed. With the very low mounted battery weight and stiffer springs, the car drives very flat and there is no real hint of oversteer on curves.

In acceleration testing, we wanted to compare the acceleration times to various speeds with the original 1957 Porsche 356A with the 1600cc engine. For me, this is the definitive Porsche Speedster.

We took the original data from the book Porsche 356, Driving in its Purest Form by Dirk-Michael Conradt. This is an excellent production history of the Porsche 356 in all variants.

The results are given below. With the new transaxle gearing, we compare very favorably through all four gears.

Conditions were 96F, wind calm on flat road.

Jack Rickard

Wednesday, August 11, 2010

Speedster Pictorial Diagrams

I've cobbled together some "pictorial diagrams" showing the wiring of the Speedster. These are a bit awkward. Rather than drawing schematics, I've kind of put together a bit of a wiring diagram using little pictures that might be more understandable to those unaccustomed to schematic diagrams, and probably annoying to those who are.

I've split these into three individual diagrams, that overlap a bit. The first is a high voltage distribution diagram. This depicts the basic distribution of your 120vdc battery pack voltage.

The second of these shows 12vdc power distribution. In the High Voltage diagram we applied pack voltage to a Chennic DC-DC converter. In this diagram, we route the output to the existing 12v distribution fuse block in the vehicle, and thence to the ignition switch and all the 12v items we've added to the car.

The Instrumentation and Control diagram shows the throttle, brake transducer, and other inputs INTO the Curtis 1238 controller to drive the car. It also depicts our added instruments to derive AH, SOC, voltage, etc from the system.

Finally, I've uploaded a Microsoft XCEL spreadsheet showing all our current Curtis 1238 configuration parameters. This spreadsheet ALSO shows all our Victron BMV600HS configuration parameters. You can download the spreadsheet here.

I've split these into three individual diagrams, that overlap a bit. The first is a high voltage distribution diagram. This depicts the basic distribution of your 120vdc battery pack voltage.

The second of these shows 12vdc power distribution. In the High Voltage diagram we applied pack voltage to a Chennic DC-DC converter. In this diagram, we route the output to the existing 12v distribution fuse block in the vehicle, and thence to the ignition switch and all the 12v items we've added to the car.

The Instrumentation and Control diagram shows the throttle, brake transducer, and other inputs INTO the Curtis 1238 controller to drive the car. It also depicts our added instruments to derive AH, SOC, voltage, etc from the system.

Finally, I've uploaded a Microsoft XCEL spreadsheet showing all our current Curtis 1238 configuration parameters. This spreadsheet ALSO shows all our Victron BMV600HS configuration parameters. You can download the spreadsheet here.

Monday, August 9, 2010

New Instrumentation for Speedster

We took two DC-3s with 26 people to a gathering of some 25 DC-3's from around the country in Rock Falls, Illinois. It was a cooling break from the weather here and a good time was had by all. We flew in formation from Rock Falls to the opening day at Oshkosh Wisconsin for the EAA Airventure 2010 air show.

It was a pleasant trip all around. Basler Turboconversions in Oshkosh hosted a lavish reception for DC-3 drivers on Tuesday night of that week. We arrived safely back in Cape Girardeau to resume one of the hottest summers here that we've had in recent years.

The heat has been oppressive. It's kept us mostly OUT of the Motor Verks. I've been primarily working on an instrument for electric cars that we can connect directly to the battery pack and derive current and voltage information via bluetooth wireless. If I can get this done, it will allow a variety of front ends on any computer or bluetooth smart phone to present current, voltage, amp hours, killowatts, killowatt hours, etc.

Of course I'm trying to learn Mac OS X Cocoa and Objective C at the same time, as I've moved to that platform mostly. It's a bit of a learning curve for an old guy. But it all happens mostly in the AIR CONDITIONING.

As a result, I've been remiss in the shooting and editing of our "weekly" show.

All that notwithstanding, it's not that there has been no progress. Actually, we've done quite a bit. We acquired the old Windisch Motor Company building down the street at 601 Morgan Oak Street. We had been more or less hemmed in by our own collection of various vehicles and components to the point that we really couldn't move cars around very well.

So we took this empty automobile dealership down the street. Built in the 1940's, it was originally a Kaiser/Fraser/Jeep dealership. In recent years, it was mostly empty with a local lumberyard using it for some storage. We've purchased the property and installed a 12,000 lb lift. We'll be doing some shooting from there when we start a larger project we have planned.

We did get our VW transaxle back and installed in Speedster part Duh. We had originally purchased a very deluxe transaxle from Long Enterprises with 3.44 rack and pinion and gears we thought would work much better with an electric drive. This transaxle was shipped to Special Editions Inc and they installed it in our roller. We built the car, and on the first test drive it became apparent there was something wrong. Any time you removed throttle in third gear the transmission would pop out of gear, often with an unappealing but at least loud noise. Not good. We went over the linkage and so forth for several weeks, but there really isn't much to it with a VW transaxle. We discussed it with Long and they readily agreed there was an internal problem.

Unfortunately, a VW transaxle based car is really pretty much built on top of a VW transaxle. More so than any other type really. You start with a transaxle, and bolt things onto it until with sufficient parts glommed onto it, you have a car. To "remove" the transaxle pretty much means total disassembly. This was a heartbreaker.

But we pulled the motor and some other rear engine compartment items and did in fact get it extracted from the vehicle. We shipped it to Long and some three weeks later received it back. They never did get very specific as to what had gone wrong, but the new one works quite well.

While it was there, we had the 0.70 4th gear replaced with a 0.93. We had had a pretty steep drop from 3rd to 4th gear. All of this was more or less intentionally designed to get our RPM's down in the sweet spot of the motor (2000-4000 rpm) for all gears. Recall in the original Speedster, we really only use 3rd and 4th gears and with the 3.88 rack and pinion, we were topping out at about 95 mph and maybe 4500 rpm. The Netgain motor would do another 1000 rpm, but was really kind of torqueless at that speed with a 120v pack. So we wanted to move things down in rpm and get 1st and 2nd gear in the game, and get our highway speeds back down in the good torque range.

We did this by going to a taller rack and pinion 3.44 vice 3.88. The early VW's used this but in recent years with the move to lower gearing, higher rpms, and closer gear ratios, it had fallen out of favor. It proved just the thing for electric drive.

But we overshot the mark a little. Going from the 1.14 third gear to the 0.70 fourth gear was a huge drop and we were seeing about 2100 rpm at 70 mph. While good for torque, it takes quite a bit of power to overcome the wind resistance at that speed and higher, and the motor cools better at a little higher rpm. So we took the opportunity during the transaxle repair to change out the 4th gear to a 0.93. It feels much more natural moving from 3rd to 4th now, and we see about 2800 rpm at 70 mph.

The results are good. I kind of enjoy driving the original Speedster in 3rd and 4th. But if you are going to produce an electric car with a 4 speed transmission, each of the gears should actually be functional and play a role in moving the vehicle. We're there.

First Gear 2.64 for 9.08 final ratio tops out at 37 mph at 4500 rpm.

Second Gear 1.93 for 6.64 final ratio tops out at 50 mph at 4500 rpm

Third Gear 1.14 for 3.92 final ratio tops out at 85 mph at 4500 rpm.

Fourth Gear 0.93 for 3.20 final ratio tops out at 104 mph at 4500 rpm.

The motor itself will go much higher RPM than the original Netgain, but again, wind resistance kind of limits us. I've driven it a steady 90 mph with a LOT of pedal left. We haven't actually found the top speed on this thing yet, but it's a felony.

Reinstalling the transaxle really brought us another somewhat pleasant surprise, though it shouldn't have been a surprise. Electric cars are just easier to work on. The first time installing everything we're measuring and building and agonizing and replacing, and changing, and doing the usual thing. But in reinstalling the transaxle, we found a curious thing. It takes about 10 minutes to install the motor the second time. It takes a few minutes to jack up the shock absorbers. But really, everything is quite clean and goes on quite easily. Electric cars are just heroically simpler devices than internal combustion vehicles. If we weren't changing/upgrading, but just replacing a blown motor, it's about a 30 minute job taking the old one out and putting a new one in. It just isn't anything.

The new transaxle allowed us to do some more regen test drives. First, I had reported the settting of the Charge Efficiency Factor on the Xantrex may have influenced our earlier regen results as I found it on AUTO for some reason after setting it at 100%. Oddly, the Speedster was set on 100% all along so that does NOT explain anything on the earlier Speedster results.

The use of kwH as a backup measurement for the regen results was likewise a dead end. It tracks our AH measurements quite linearly. Our meters are working.

As it turns out, it appears "I" was actually the problem with the results. More accurately, the driver, and by extension, the driving style, can quite swamp the efficiency gains of regenerative braking.

We did six more test drives, again in mostly urban traffic with hills, stop lights, and mucho traffic.

Without regenerative braking, I did a 21.317 mile loop to Jackson Missouri using 34.2 AH or 1.609 AH per mile to make the trip. It took 4.839 kwH to recharge the car for 227 wH per mile.

WITH regenerative braking, I did the same trip in 35.0 AH for 1.642 AH per mile and it took 4.860 kwH to recharge the vehicle for 228 wH per mile.

Just like our initial tests, I actually had a NEGATIVE efficiency gain using regenerative braking.

We sent Brain on the same drive.

With no regenerative braking this guy is a watt-hog. He did a 21.19 mile loop in 39.5 AH for 1.864 AH per mile and used 5.403 kwH to recharge the car for 255 wH per mile.

WITH regenerative braking, he was back down to 33.6 AH for the identical distance reading indicating 1.585 AH per mile. On recharge, he used a more economical 4.789 kwH for 226 wH per mile. This is a 14.93% efficiency gain from regenerative braking for the Brain.

Trace Jessup repeated the test. With no regenerative braking, he did a loop of 21.34 miles using 36.4 AH for a 1.705 AH/mile result and recharged with 4.972kwH for 233 wH per mile.

With regenerative braking, he did a 21.19 mile loop in 34.4 AH for 1.623 AH/mile and recharged at 4.895 kwH for 231 wH per mile. This was a more modest gain of a little under 5%.

The bottom line appears to be that you can get any result you want, depending on how you drive. But the other conclusion inescapably is that how you drive the car rather swamps whatever technology you buy and install.

I don't think of myself as "hypermiling" to get my results. It feels to me like normal driving. But I do have a couple of years behind the wheel of our original Speedster project. It has no regenerative braking and freewheels very nicely when you ease of f the throttle. This was a little disconcerting at first as you expect a car to slow down when you ease off the throttle. But I quickly became used to it and kind of developed a "push and glide" driving style that is very hard to NOT do when driving part DUH with no regen.

I would note that the regenerative braking, with about 10% of neutral braking on the throttle, very closely approximates the feel of a normal car. The brake regen gives it a kind of power brake feel, and the neutral braking on the throttle simulates engine compression a bit. It is undoubtedly the best setup for new drivers. It DOES require you to give up the clutchless shifting, but if you've never had that, it's not much of a loss. You just shift like you would any sports car, and it works fine.

We did receive a replacement air conditioning compressor AND controller from Revolt in Texas - actually drop shlpped from Tecumseh. A couple of interesting and somewhat disappointing notes.

First, the admonition that we SHOULD have added oil to the original compressor, which wasn't mentioned in ANY of the documentation, turns out to be a bit bogus. Tecumseh advises that the compressor is shipped with 290cc of oil in it and no additions should be made unless you pump the oil out of the compressor. The original compressor from its first instant made a HUGE racket. Not having ever used one before, I was unsure, but it just didn't sound like it could possibly be happy.

It wasn't. The replacement puts out a very audible purr, but it is nothing compared to the original compressors complaint.

The second problem we were having is a bit pernicious. The controller and compressor work very well to air condition the Mini Cooper - in the garage. And I do mean it works very well. Very nice cool temperatures out of the vents and it feels like a POWERFUL air conditioner. You can adjust the rpm, and thus the output of the compressor, quite widely. But it has little effect on the air conditioning system.

The problem is in driving the car. If you drive very nicely and somewhat sedately, it works well. But on acceleration, you can note a distinct drop in rpm from the a/c compressor. But if you accelerate smartly, it actually drops to nothing and never comes back. And in the process blows the 30 amp input fuse to the controller.

I don't quite understand this. The controller appears to draw about 5.5 amps from our pack normally in the garage. Our pack voltage is nominally 375 volts. If I accelerate strongly, this sags to about 345 volts. This is quite normal, and quite expected. It would certainly be this way with any battery pack, even lead acid cells.

But the current to the controller apparently then exceeds 30 amps and the power to the compressor reduces such that the compressor stalls. We tried this at several settings of the compressor, from minimum to maximum with the same result. Worse, the fusing does not appear to do its job. After about three blown fuses, you also have a very dead controller.

When we talked to Revolt about it, they note that it works very well with 144v systems. The controller is rated for 120-420vdc, but they really haven't ever had anyone operate it at 375v before. So we're kind of the beta test crew. First bug report: it doesn't work.

So all we need is a 375v 3kw 3-phase controller, that has sufficient voltage regulation to keep from killing itself, and we would have air conditioning. Very discouraging. I've ordered THIS from eBay and we'll experiment with it a bit... but I'm not hopeful. If any of you have any ideas as to what we're doing wrong or how to fix it.....

Finally, we've been struggling with the Xantrex instrumentation. We had originally powered this by tapping off the first 10 cells of our pack. They list 6ma as their power requirements. That turns out to be WITHOUT the backlight. With the backlight, it is more like 70ma and of course we had this running 24x7.

The real fix is to use a DC-DC converter to power it, but you lose the ability to read your pack voltage if you do that. So we did a little voltage divider using 10W resistors and a pot that we could adjust to calibrate our 5:1 divider so that it showed true pack voltage. This is all well and good, but the divider itself then consumes power and the drain on the pack works out to 5 or 6 AH daily. And the resistors actually get hot.

Damien Maguire of Ireland suggested we got to a VIctron Energy BMV600HS. The HS model can go up to 360volts, does its own measurement and power conversion, and is a MUCH simpler install than the Xantrex. Their shunt and circuit board is actually in a very nice weatherproof box and the connection to the actual gage is a simple telephone cable. It will really be much easier for Special Editions Inc to install.

The device is $405 and kind of hard to find. We found it at Peter Kennedy Yacht Services http://www.pkys.com. The HS version is NOT actually shown on his web site, but contact him and he can get you one. Reasonable delivery time. We like it.

The display is a little harder to read, and the setup is a little more confusing. But it is basically the same function and features as the Xantrex. We use the relay at 10%SOC to connect a 4k resistor between our ground and signal wires coming from the throttle. This reduces the throttle input to the controller. So when you get down to 10%SOC you have to give it full pedal to get the car up to about 20 mph. This is an excellent way to signal there is a problem (like recharge the car). I've actually tested this and you can indeed "limp" home although it is slow.

We'll try to do better on our weekly videos. Lots of stuff going on and happening.

Jack RIckard

It was a pleasant trip all around. Basler Turboconversions in Oshkosh hosted a lavish reception for DC-3 drivers on Tuesday night of that week. We arrived safely back in Cape Girardeau to resume one of the hottest summers here that we've had in recent years.

The heat has been oppressive. It's kept us mostly OUT of the Motor Verks. I've been primarily working on an instrument for electric cars that we can connect directly to the battery pack and derive current and voltage information via bluetooth wireless. If I can get this done, it will allow a variety of front ends on any computer or bluetooth smart phone to present current, voltage, amp hours, killowatts, killowatt hours, etc.

Of course I'm trying to learn Mac OS X Cocoa and Objective C at the same time, as I've moved to that platform mostly. It's a bit of a learning curve for an old guy. But it all happens mostly in the AIR CONDITIONING.

As a result, I've been remiss in the shooting and editing of our "weekly" show.

All that notwithstanding, it's not that there has been no progress. Actually, we've done quite a bit. We acquired the old Windisch Motor Company building down the street at 601 Morgan Oak Street. We had been more or less hemmed in by our own collection of various vehicles and components to the point that we really couldn't move cars around very well.

So we took this empty automobile dealership down the street. Built in the 1940's, it was originally a Kaiser/Fraser/Jeep dealership. In recent years, it was mostly empty with a local lumberyard using it for some storage. We've purchased the property and installed a 12,000 lb lift. We'll be doing some shooting from there when we start a larger project we have planned.

We did get our VW transaxle back and installed in Speedster part Duh. We had originally purchased a very deluxe transaxle from Long Enterprises with 3.44 rack and pinion and gears we thought would work much better with an electric drive. This transaxle was shipped to Special Editions Inc and they installed it in our roller. We built the car, and on the first test drive it became apparent there was something wrong. Any time you removed throttle in third gear the transmission would pop out of gear, often with an unappealing but at least loud noise. Not good. We went over the linkage and so forth for several weeks, but there really isn't much to it with a VW transaxle. We discussed it with Long and they readily agreed there was an internal problem.

Unfortunately, a VW transaxle based car is really pretty much built on top of a VW transaxle. More so than any other type really. You start with a transaxle, and bolt things onto it until with sufficient parts glommed onto it, you have a car. To "remove" the transaxle pretty much means total disassembly. This was a heartbreaker.

But we pulled the motor and some other rear engine compartment items and did in fact get it extracted from the vehicle. We shipped it to Long and some three weeks later received it back. They never did get very specific as to what had gone wrong, but the new one works quite well.

While it was there, we had the 0.70 4th gear replaced with a 0.93. We had had a pretty steep drop from 3rd to 4th gear. All of this was more or less intentionally designed to get our RPM's down in the sweet spot of the motor (2000-4000 rpm) for all gears. Recall in the original Speedster, we really only use 3rd and 4th gears and with the 3.88 rack and pinion, we were topping out at about 95 mph and maybe 4500 rpm. The Netgain motor would do another 1000 rpm, but was really kind of torqueless at that speed with a 120v pack. So we wanted to move things down in rpm and get 1st and 2nd gear in the game, and get our highway speeds back down in the good torque range.

We did this by going to a taller rack and pinion 3.44 vice 3.88. The early VW's used this but in recent years with the move to lower gearing, higher rpms, and closer gear ratios, it had fallen out of favor. It proved just the thing for electric drive.

But we overshot the mark a little. Going from the 1.14 third gear to the 0.70 fourth gear was a huge drop and we were seeing about 2100 rpm at 70 mph. While good for torque, it takes quite a bit of power to overcome the wind resistance at that speed and higher, and the motor cools better at a little higher rpm. So we took the opportunity during the transaxle repair to change out the 4th gear to a 0.93. It feels much more natural moving from 3rd to 4th now, and we see about 2800 rpm at 70 mph.

The results are good. I kind of enjoy driving the original Speedster in 3rd and 4th. But if you are going to produce an electric car with a 4 speed transmission, each of the gears should actually be functional and play a role in moving the vehicle. We're there.

First Gear 2.64 for 9.08 final ratio tops out at 37 mph at 4500 rpm.

Second Gear 1.93 for 6.64 final ratio tops out at 50 mph at 4500 rpm

Third Gear 1.14 for 3.92 final ratio tops out at 85 mph at 4500 rpm.

Fourth Gear 0.93 for 3.20 final ratio tops out at 104 mph at 4500 rpm.

The motor itself will go much higher RPM than the original Netgain, but again, wind resistance kind of limits us. I've driven it a steady 90 mph with a LOT of pedal left. We haven't actually found the top speed on this thing yet, but it's a felony.

Reinstalling the transaxle really brought us another somewhat pleasant surprise, though it shouldn't have been a surprise. Electric cars are just easier to work on. The first time installing everything we're measuring and building and agonizing and replacing, and changing, and doing the usual thing. But in reinstalling the transaxle, we found a curious thing. It takes about 10 minutes to install the motor the second time. It takes a few minutes to jack up the shock absorbers. But really, everything is quite clean and goes on quite easily. Electric cars are just heroically simpler devices than internal combustion vehicles. If we weren't changing/upgrading, but just replacing a blown motor, it's about a 30 minute job taking the old one out and putting a new one in. It just isn't anything.

The new transaxle allowed us to do some more regen test drives. First, I had reported the settting of the Charge Efficiency Factor on the Xantrex may have influenced our earlier regen results as I found it on AUTO for some reason after setting it at 100%. Oddly, the Speedster was set on 100% all along so that does NOT explain anything on the earlier Speedster results.

The use of kwH as a backup measurement for the regen results was likewise a dead end. It tracks our AH measurements quite linearly. Our meters are working.

As it turns out, it appears "I" was actually the problem with the results. More accurately, the driver, and by extension, the driving style, can quite swamp the efficiency gains of regenerative braking.

We did six more test drives, again in mostly urban traffic with hills, stop lights, and mucho traffic.

Without regenerative braking, I did a 21.317 mile loop to Jackson Missouri using 34.2 AH or 1.609 AH per mile to make the trip. It took 4.839 kwH to recharge the car for 227 wH per mile.

WITH regenerative braking, I did the same trip in 35.0 AH for 1.642 AH per mile and it took 4.860 kwH to recharge the vehicle for 228 wH per mile.

Just like our initial tests, I actually had a NEGATIVE efficiency gain using regenerative braking.

We sent Brain on the same drive.

With no regenerative braking this guy is a watt-hog. He did a 21.19 mile loop in 39.5 AH for 1.864 AH per mile and used 5.403 kwH to recharge the car for 255 wH per mile.

WITH regenerative braking, he was back down to 33.6 AH for the identical distance reading indicating 1.585 AH per mile. On recharge, he used a more economical 4.789 kwH for 226 wH per mile. This is a 14.93% efficiency gain from regenerative braking for the Brain.

Trace Jessup repeated the test. With no regenerative braking, he did a loop of 21.34 miles using 36.4 AH for a 1.705 AH/mile result and recharged with 4.972kwH for 233 wH per mile.

With regenerative braking, he did a 21.19 mile loop in 34.4 AH for 1.623 AH/mile and recharged at 4.895 kwH for 231 wH per mile. This was a more modest gain of a little under 5%.

The bottom line appears to be that you can get any result you want, depending on how you drive. But the other conclusion inescapably is that how you drive the car rather swamps whatever technology you buy and install.

I don't think of myself as "hypermiling" to get my results. It feels to me like normal driving. But I do have a couple of years behind the wheel of our original Speedster project. It has no regenerative braking and freewheels very nicely when you ease of f the throttle. This was a little disconcerting at first as you expect a car to slow down when you ease off the throttle. But I quickly became used to it and kind of developed a "push and glide" driving style that is very hard to NOT do when driving part DUH with no regen.

I would note that the regenerative braking, with about 10% of neutral braking on the throttle, very closely approximates the feel of a normal car. The brake regen gives it a kind of power brake feel, and the neutral braking on the throttle simulates engine compression a bit. It is undoubtedly the best setup for new drivers. It DOES require you to give up the clutchless shifting, but if you've never had that, it's not much of a loss. You just shift like you would any sports car, and it works fine.

We did receive a replacement air conditioning compressor AND controller from Revolt in Texas - actually drop shlpped from Tecumseh. A couple of interesting and somewhat disappointing notes.

First, the admonition that we SHOULD have added oil to the original compressor, which wasn't mentioned in ANY of the documentation, turns out to be a bit bogus. Tecumseh advises that the compressor is shipped with 290cc of oil in it and no additions should be made unless you pump the oil out of the compressor. The original compressor from its first instant made a HUGE racket. Not having ever used one before, I was unsure, but it just didn't sound like it could possibly be happy.

It wasn't. The replacement puts out a very audible purr, but it is nothing compared to the original compressors complaint.

The second problem we were having is a bit pernicious. The controller and compressor work very well to air condition the Mini Cooper - in the garage. And I do mean it works very well. Very nice cool temperatures out of the vents and it feels like a POWERFUL air conditioner. You can adjust the rpm, and thus the output of the compressor, quite widely. But it has little effect on the air conditioning system.

The problem is in driving the car. If you drive very nicely and somewhat sedately, it works well. But on acceleration, you can note a distinct drop in rpm from the a/c compressor. But if you accelerate smartly, it actually drops to nothing and never comes back. And in the process blows the 30 amp input fuse to the controller.

I don't quite understand this. The controller appears to draw about 5.5 amps from our pack normally in the garage. Our pack voltage is nominally 375 volts. If I accelerate strongly, this sags to about 345 volts. This is quite normal, and quite expected. It would certainly be this way with any battery pack, even lead acid cells.

But the current to the controller apparently then exceeds 30 amps and the power to the compressor reduces such that the compressor stalls. We tried this at several settings of the compressor, from minimum to maximum with the same result. Worse, the fusing does not appear to do its job. After about three blown fuses, you also have a very dead controller.

When we talked to Revolt about it, they note that it works very well with 144v systems. The controller is rated for 120-420vdc, but they really haven't ever had anyone operate it at 375v before. So we're kind of the beta test crew. First bug report: it doesn't work.

So all we need is a 375v 3kw 3-phase controller, that has sufficient voltage regulation to keep from killing itself, and we would have air conditioning. Very discouraging. I've ordered THIS from eBay and we'll experiment with it a bit... but I'm not hopeful. If any of you have any ideas as to what we're doing wrong or how to fix it.....

Finally, we've been struggling with the Xantrex instrumentation. We had originally powered this by tapping off the first 10 cells of our pack. They list 6ma as their power requirements. That turns out to be WITHOUT the backlight. With the backlight, it is more like 70ma and of course we had this running 24x7.

The real fix is to use a DC-DC converter to power it, but you lose the ability to read your pack voltage if you do that. So we did a little voltage divider using 10W resistors and a pot that we could adjust to calibrate our 5:1 divider so that it showed true pack voltage. This is all well and good, but the divider itself then consumes power and the drain on the pack works out to 5 or 6 AH daily. And the resistors actually get hot.

Damien Maguire of Ireland suggested we got to a VIctron Energy BMV600HS. The HS model can go up to 360volts, does its own measurement and power conversion, and is a MUCH simpler install than the Xantrex. Their shunt and circuit board is actually in a very nice weatherproof box and the connection to the actual gage is a simple telephone cable. It will really be much easier for Special Editions Inc to install.

The device is $405 and kind of hard to find. We found it at Peter Kennedy Yacht Services http://www.pkys.com. The HS version is NOT actually shown on his web site, but contact him and he can get you one. Reasonable delivery time. We like it.

The display is a little harder to read, and the setup is a little more confusing. But it is basically the same function and features as the Xantrex. We use the relay at 10%SOC to connect a 4k resistor between our ground and signal wires coming from the throttle. This reduces the throttle input to the controller. So when you get down to 10%SOC you have to give it full pedal to get the car up to about 20 mph. This is an excellent way to signal there is a problem (like recharge the car). I've actually tested this and you can indeed "limp" home although it is slow.

We'll try to do better on our weekly videos. Lots of stuff going on and happening.

Jack RIckard

Subscribe to:

Posts (Atom)